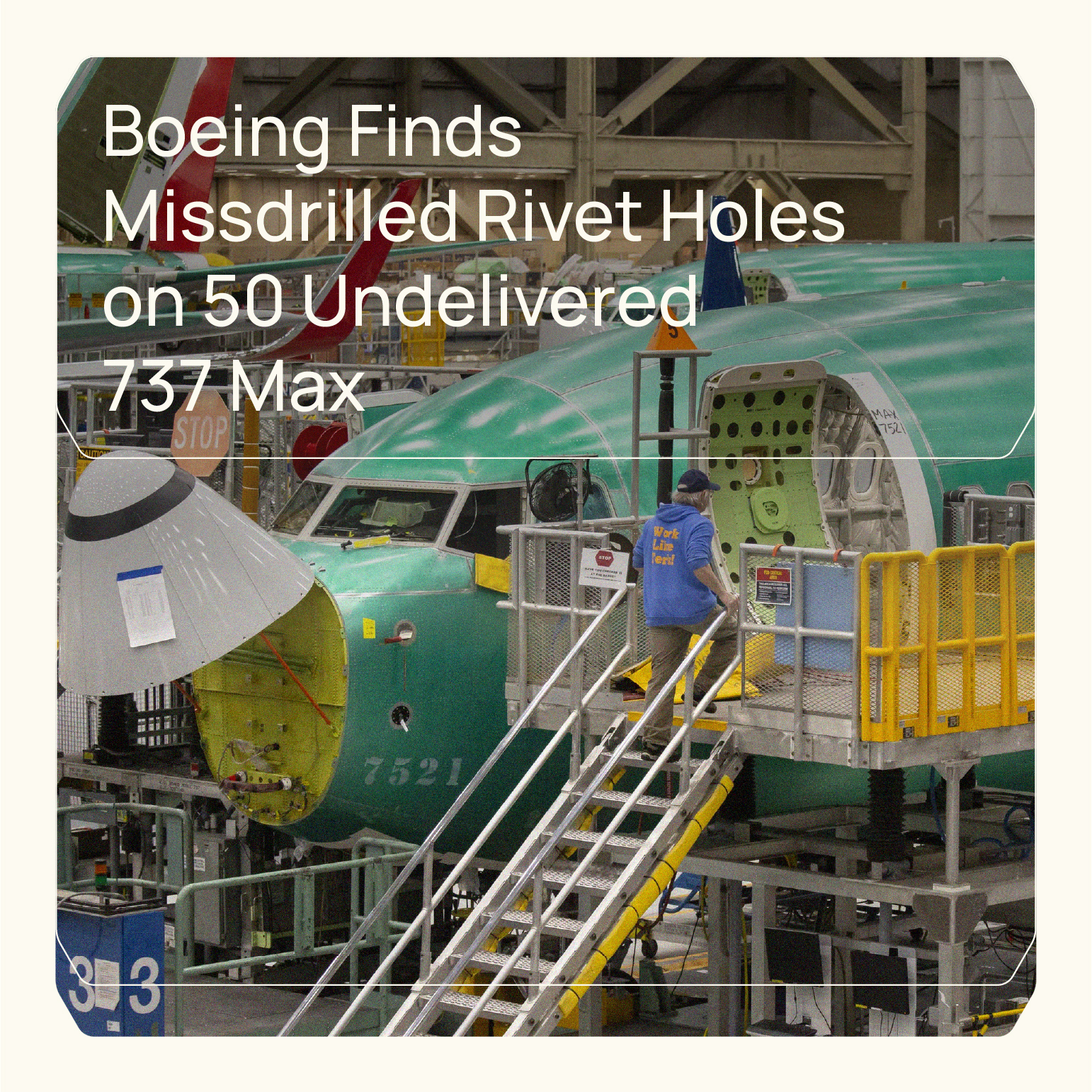

Boeing Finds Missdrilled Rivet Holes on 50 Undelivered 737 Max

Tsamouris, the Fastener Specialists©

Back in February 2024, Boeing announced that it has discovered incorrectly drilled holes in the fuselages of approximately 50 undelivered 737 Max jets. This setback was expected to cause rework and potentially delay the delivery of these planes, raising further concerns about quality control at the manufacturer and its suppliers.

Stan Deal, the CEO of Boeing's commercial plane unit, stated in a memo to employees that a supplier had identified two holes that may not have been drilled according to the company's requirements. While Deal emphasized that this issue is not an immediate flight safety concern and that the 737s currently in use can continue flying, it underscores the ongoing challenges faced by Boeing and its suppliers in maintaining high standards of quality and safety.

The latest problems come on the heels of a January 5th, 2024, incident involving a 737 Max 9 jet operated by Alaska Airlines, in which a panel blew out mid-flight due to missing bolts, forcing an emergency landing and the grounding of some Max 9s in the United States. Reports have suggested that Boeing workers had previously opened and reinstalled the panel that blew off the Alaska Airlines plane, raising further questions about quality control practices.

In response to these issues, the Federal Aviation Administration (FAA) has stated that it will limit Boeing's output until it is confident in the company's quality control processes. The regulator is also investigating Boeing's manufacturing practices and production lines, including those involving Spirit AeroSystems, Boeing's fuselage supplier.

At Tsamouris, we understand the critical importance of quality control and precision in the manufacturing process, particularly when it comes to fasteners and components that play a vital role in ensuring the safety and reliability of aircrafts.

Back in February 2024, Boeing announced that it has discovered incorrectly drilled holes in the fuselages of approximately 50 undelivered 737 Max jets. This setback was expected to cause rework and potentially delay the delivery of these planes, raising further concerns about quality control at the manufacturer and its suppliers.

Stan Deal, the CEO of Boeing's commercial plane unit, stated in a memo to employees that a supplier had identified two holes that may not have been drilled according to the company's requirements. While Deal emphasized that this issue is not an immediate flight safety concern and that the 737s currently in use can continue flying, it underscores the ongoing challenges faced by Boeing and its suppliers in maintaining high standards of quality and safety.

The latest problems come on the heels of a January 5th, 2024, incident involving a 737 Max 9 jet operated by Alaska Airlines, in which a panel blew out mid-flight due to missing bolts, forcing an emergency landing and the grounding of some Max 9s in the United States. Reports have suggested that Boeing workers had previously opened and reinstalled the panel that blew off the Alaska Airlines plane, raising further questions about quality control practices.

In response to these issues, the Federal Aviation Administration (FAA) has stated that it will limit Boeing's output until it is confident in the company's quality control processes. The regulator is also investigating Boeing's manufacturing practices and production lines, including those involving Spirit AeroSystems, Boeing's fuselage supplier.

At Tsamouris, we understand the critical importance of quality control and precision in the manufacturing process, particularly when it comes to fasteners and components that play a vital role in ensuring the safety and reliability of aircrafts.

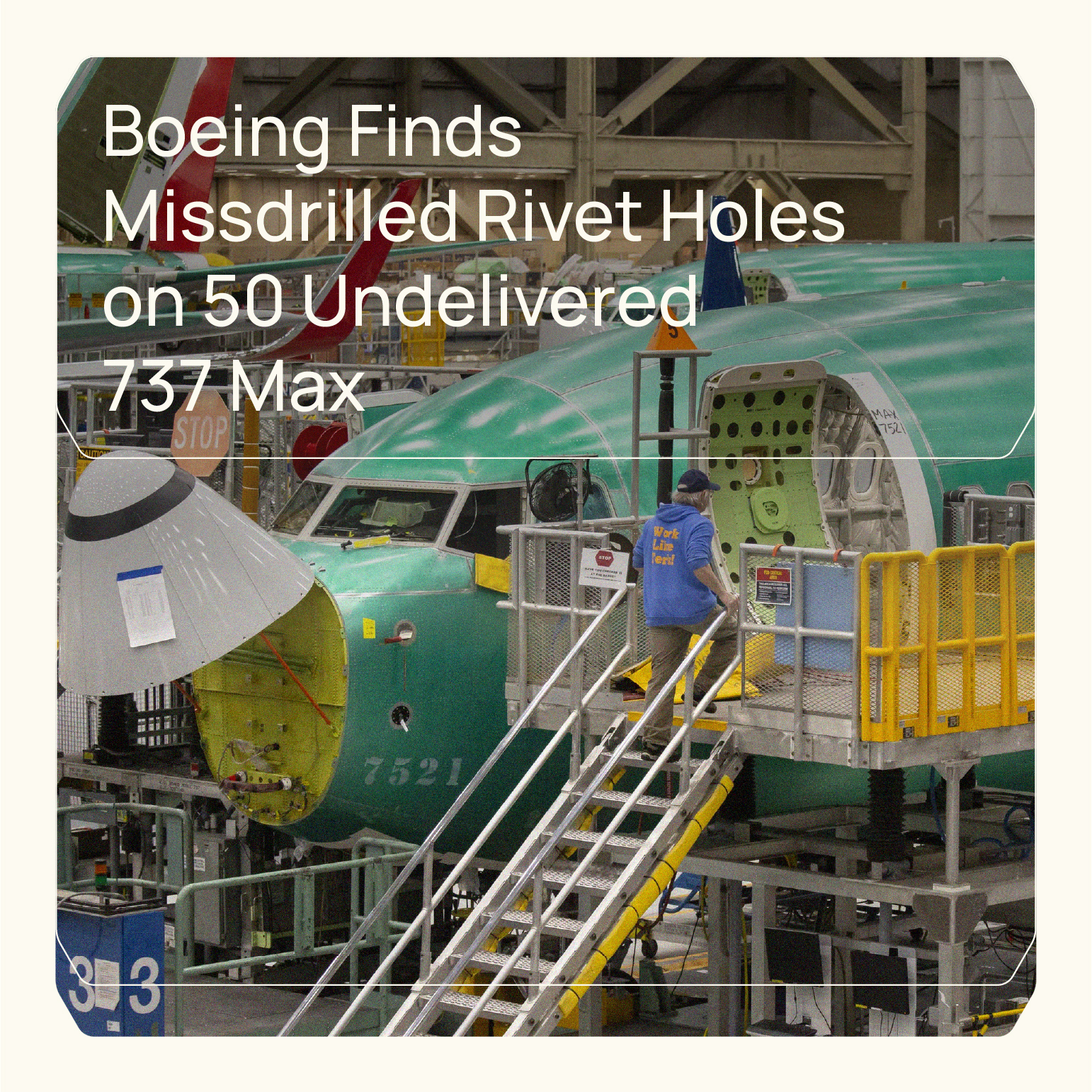

Boeing Finds Missdrilled Rivet Holes on 50 Undelivered 737 Max

Tsamouris, the Fastener Specialists©

Back in February 2024, Boeing announced that it has discovered incorrectly drilled holes in the fuselages of approximately 50 undelivered 737 Max jets. This setback was expected to cause rework and potentially delay the delivery of these planes, raising further concerns about quality control at the manufacturer and its suppliers.

Stan Deal, the CEO of Boeing's commercial plane unit, stated in a memo to employees that a supplier had identified two holes that may not have been drilled according to the company's requirements. While Deal emphasized that this issue is not an immediate flight safety concern and that the 737s currently in use can continue flying, it underscores the ongoing challenges faced by Boeing and its suppliers in maintaining high standards of quality and safety.

The latest problems come on the heels of a January 5th, 2024, incident involving a 737 Max 9 jet operated by Alaska Airlines, in which a panel blew out mid-flight due to missing bolts, forcing an emergency landing and the grounding of some Max 9s in the United States. Reports have suggested that Boeing workers had previously opened and reinstalled the panel that blew off the Alaska Airlines plane, raising further questions about quality control practices.

In response to these issues, the Federal Aviation Administration (FAA) has stated that it will limit Boeing's output until it is confident in the company's quality control processes. The regulator is also investigating Boeing's manufacturing practices and production lines, including those involving Spirit AeroSystems, Boeing's fuselage supplier.

At Tsamouris, we understand the critical importance of quality control and precision in the manufacturing process, particularly when it comes to fasteners and components that play a vital role in ensuring the safety and reliability of aircrafts.

Back in February 2024, Boeing announced that it has discovered incorrectly drilled holes in the fuselages of approximately 50 undelivered 737 Max jets. This setback was expected to cause rework and potentially delay the delivery of these planes, raising further concerns about quality control at the manufacturer and its suppliers.

Stan Deal, the CEO of Boeing's commercial plane unit, stated in a memo to employees that a supplier had identified two holes that may not have been drilled according to the company's requirements. While Deal emphasized that this issue is not an immediate flight safety concern and that the 737s currently in use can continue flying, it underscores the ongoing challenges faced by Boeing and its suppliers in maintaining high standards of quality and safety.

The latest problems come on the heels of a January 5th, 2024, incident involving a 737 Max 9 jet operated by Alaska Airlines, in which a panel blew out mid-flight due to missing bolts, forcing an emergency landing and the grounding of some Max 9s in the United States. Reports have suggested that Boeing workers had previously opened and reinstalled the panel that blew off the Alaska Airlines plane, raising further questions about quality control practices.

In response to these issues, the Federal Aviation Administration (FAA) has stated that it will limit Boeing's output until it is confident in the company's quality control processes. The regulator is also investigating Boeing's manufacturing practices and production lines, including those involving Spirit AeroSystems, Boeing's fuselage supplier.

At Tsamouris, we understand the critical importance of quality control and precision in the manufacturing process, particularly when it comes to fasteners and components that play a vital role in ensuring the safety and reliability of aircrafts.

Latest News