How a Loose Bolt Led to China Airlines Boeing 737 Explosion

Tsamouris, the Fastener Specialists©

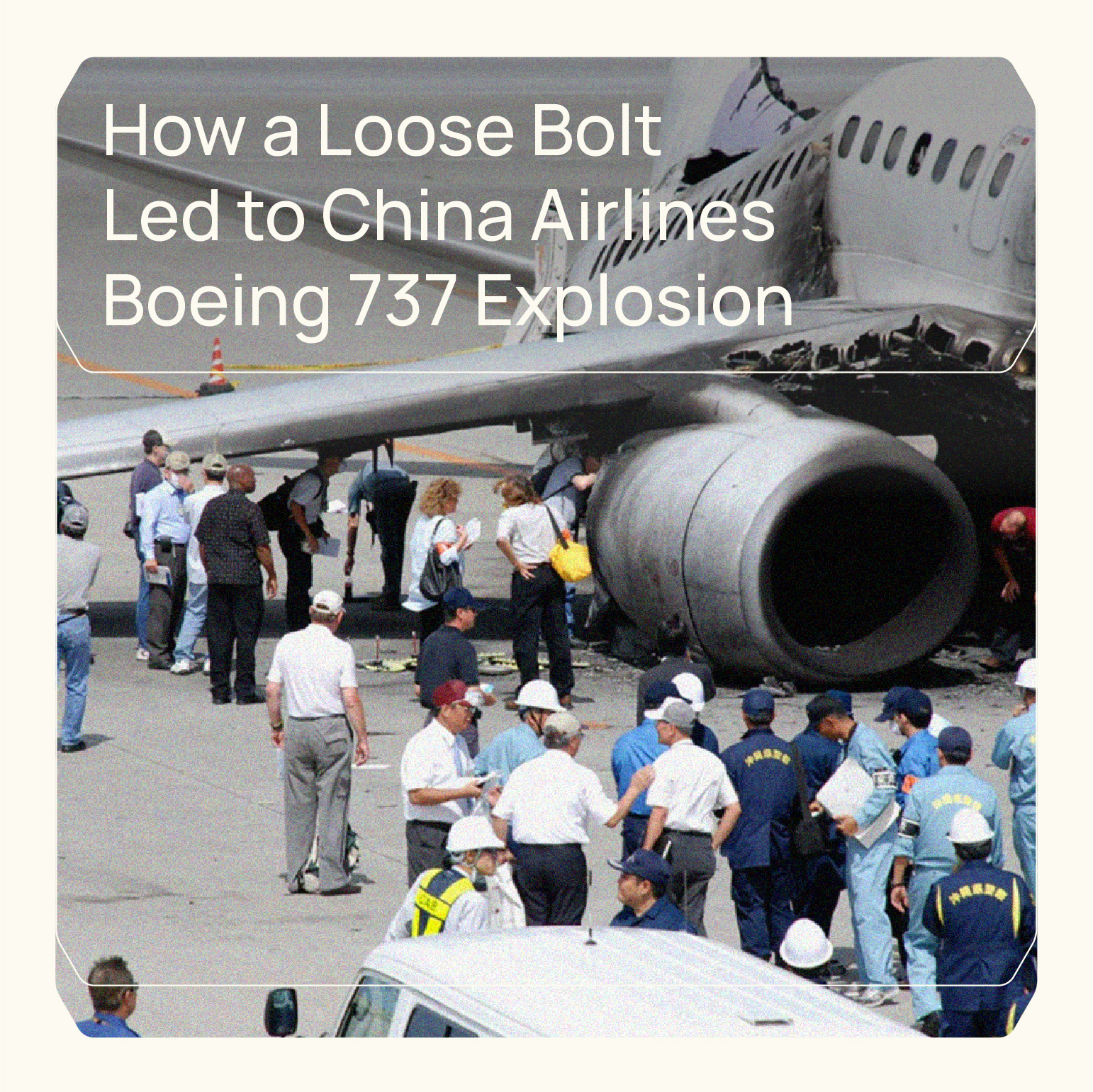

In August 2007, a seemingly minor maintenance oversight led to a near-fatal accident during China Airlines Flight 120. Fortunately, there were no casualties. The Boeing 737-800, carrying 157 passengers and 8 crew members, caught fire and exploded at Naha Airport in Japan shortly after landing safely from Taipei and after all passengers had evacuated.

The incident unfolded as the crew prepared for disembarkation, having taxied the aircraft to the gate and shut off the engines. Suddenly, ground crew members noticed flames emanating from one of the engines and promptly informed air traffic control. The captain, upon being alerted, ordered an emergency evacuation. Miraculously, all passengers and crew managed to evacuate the aircraft through the four hatches using slides, just moments before the plane exploded. The pilots, having ensured everyone's safety, exited through the cockpit window. Despite the harrowing experience, only minor injuries were reported.

The on-site investigation revealed that fuel had leaked from a puncture hole in a slat's track. Further inquiry uncovered that an incorrectly installed bolt in the right-wing of the aircraft's slat down-stop had worked itself loose. The bolt had been torqued without the requisite washer during scheduled maintenance six weeks prior. Consequently, the nut came loose, causing the entire down-stop assembly to detach and fall onto the slat-can assembly track during ground movement.

As the slat retracted, it pushed the detached assembly, eventually forcing the downstop bolt through the slat-can wall, puncturing the fuel tank. The leaking fuel ignited upon contact with high-temperature areas on the right engine, leading to the fire and explosions.

Shockingly, the cause of this near-disaster was traced back to a single missing washer, which was found lying just below the opening in the wing forward spar.

In the aftermath of the incident, the Republic of China Civil Aeronautics Administration grounded the entire fleet of Boeing 737-800s operated by China Airlines, Mandarin Airlines, and the Republic of China Air Force for fuel system inspections. The Japanese Civil Aviation Bureau followed suit, requesting inspections of aircraft of the same type operated by Japanese carriers.

In August 2007, a seemingly minor maintenance oversight led to a near-fatal accident during China Airlines Flight 120. Fortunately, there were no casualties. The Boeing 737-800, carrying 157 passengers and 8 crew members, caught fire and exploded at Naha Airport in Japan shortly after landing safely from Taipei and after all passengers had evacuated.

The incident unfolded as the crew prepared for disembarkation, having taxied the aircraft to the gate and shut off the engines. Suddenly, ground crew members noticed flames emanating from one of the engines and promptly informed air traffic control. The captain, upon being alerted, ordered an emergency evacuation. Miraculously, all passengers and crew managed to evacuate the aircraft through the four hatches using slides, just moments before the plane exploded. The pilots, having ensured everyone's safety, exited through the cockpit window. Despite the harrowing experience, only minor injuries were reported.

The on-site investigation revealed that fuel had leaked from a puncture hole in a slat's track. Further inquiry uncovered that an incorrectly installed bolt in the right-wing of the aircraft's slat down-stop had worked itself loose. The bolt had been torqued without the requisite washer during scheduled maintenance six weeks prior. Consequently, the nut came loose, causing the entire down-stop assembly to detach and fall onto the slat-can assembly track during ground movement.

As the slat retracted, it pushed the detached assembly, eventually forcing the downstop bolt through the slat-can wall, puncturing the fuel tank. The leaking fuel ignited upon contact with high-temperature areas on the right engine, leading to the fire and explosions.

Shockingly, the cause of this near-disaster was traced back to a single missing washer, which was found lying just below the opening in the wing forward spar.

In the aftermath of the incident, the Republic of China Civil Aeronautics Administration grounded the entire fleet of Boeing 737-800s operated by China Airlines, Mandarin Airlines, and the Republic of China Air Force for fuel system inspections. The Japanese Civil Aviation Bureau followed suit, requesting inspections of aircraft of the same type operated by Japanese carriers.

How a Loose Bolt Led to China Airlines Boeing 737 Explosion

Tsamouris, the Fastener Specialists©

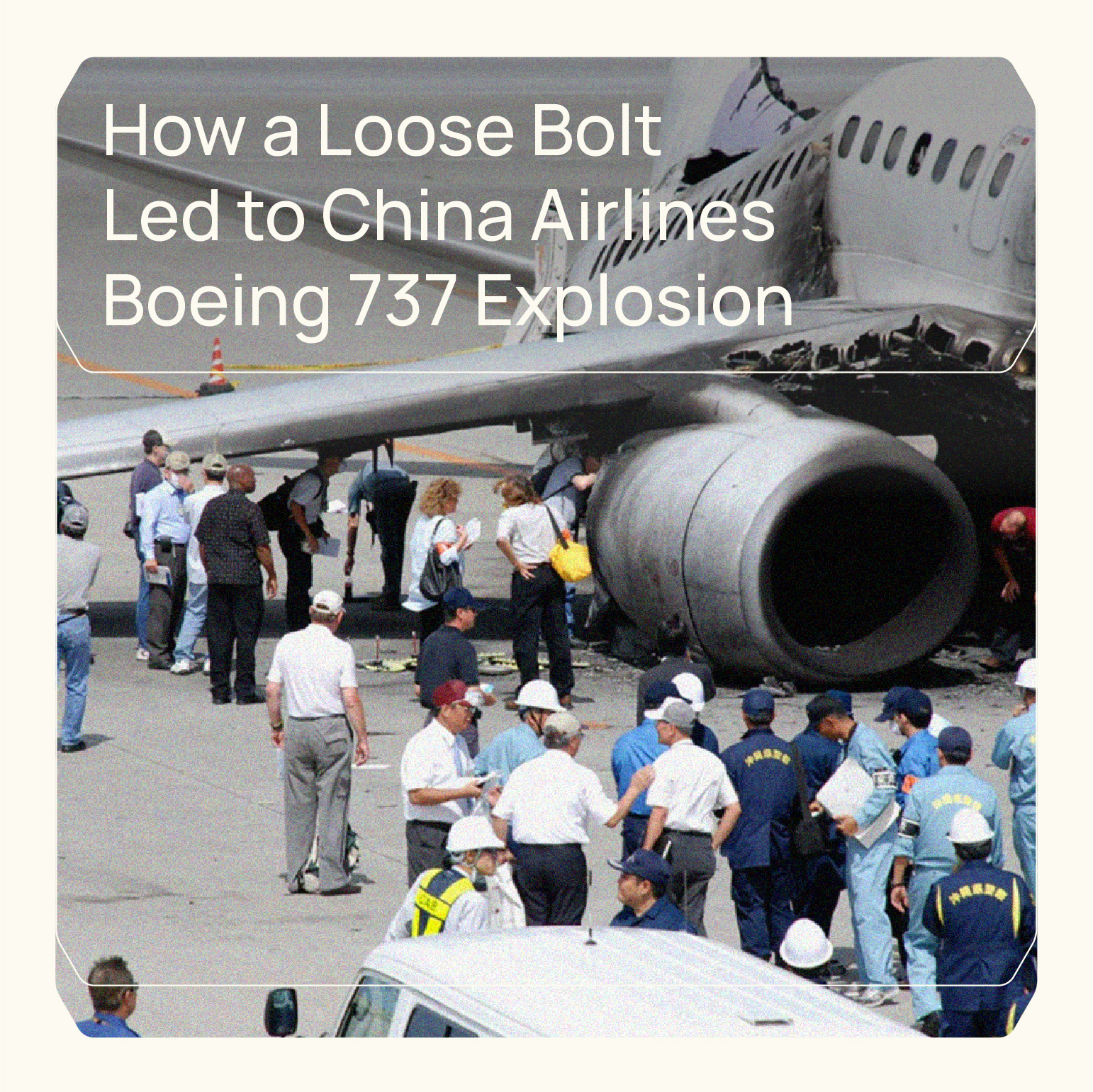

In August 2007, a seemingly minor maintenance oversight led to a near-fatal accident during China Airlines Flight 120. Fortunately, there were no casualties. The Boeing 737-800, carrying 157 passengers and 8 crew members, caught fire and exploded at Naha Airport in Japan shortly after landing safely from Taipei and after all passengers had evacuated.

The incident unfolded as the crew prepared for disembarkation, having taxied the aircraft to the gate and shut off the engines. Suddenly, ground crew members noticed flames emanating from one of the engines and promptly informed air traffic control. The captain, upon being alerted, ordered an emergency evacuation. Miraculously, all passengers and crew managed to evacuate the aircraft through the four hatches using slides, just moments before the plane exploded. The pilots, having ensured everyone's safety, exited through the cockpit window. Despite the harrowing experience, only minor injuries were reported.

The on-site investigation revealed that fuel had leaked from a puncture hole in a slat's track. Further inquiry uncovered that an incorrectly installed bolt in the right-wing of the aircraft's slat down-stop had worked itself loose. The bolt had been torqued without the requisite washer during scheduled maintenance six weeks prior. Consequently, the nut came loose, causing the entire down-stop assembly to detach and fall onto the slat-can assembly track during ground movement.

As the slat retracted, it pushed the detached assembly, eventually forcing the downstop bolt through the slat-can wall, puncturing the fuel tank. The leaking fuel ignited upon contact with high-temperature areas on the right engine, leading to the fire and explosions.

Shockingly, the cause of this near-disaster was traced back to a single missing washer, which was found lying just below the opening in the wing forward spar.

In the aftermath of the incident, the Republic of China Civil Aeronautics Administration grounded the entire fleet of Boeing 737-800s operated by China Airlines, Mandarin Airlines, and the Republic of China Air Force for fuel system inspections. The Japanese Civil Aviation Bureau followed suit, requesting inspections of aircraft of the same type operated by Japanese carriers.

In August 2007, a seemingly minor maintenance oversight led to a near-fatal accident during China Airlines Flight 120. Fortunately, there were no casualties. The Boeing 737-800, carrying 157 passengers and 8 crew members, caught fire and exploded at Naha Airport in Japan shortly after landing safely from Taipei and after all passengers had evacuated.

The incident unfolded as the crew prepared for disembarkation, having taxied the aircraft to the gate and shut off the engines. Suddenly, ground crew members noticed flames emanating from one of the engines and promptly informed air traffic control. The captain, upon being alerted, ordered an emergency evacuation. Miraculously, all passengers and crew managed to evacuate the aircraft through the four hatches using slides, just moments before the plane exploded. The pilots, having ensured everyone's safety, exited through the cockpit window. Despite the harrowing experience, only minor injuries were reported.

The on-site investigation revealed that fuel had leaked from a puncture hole in a slat's track. Further inquiry uncovered that an incorrectly installed bolt in the right-wing of the aircraft's slat down-stop had worked itself loose. The bolt had been torqued without the requisite washer during scheduled maintenance six weeks prior. Consequently, the nut came loose, causing the entire down-stop assembly to detach and fall onto the slat-can assembly track during ground movement.

As the slat retracted, it pushed the detached assembly, eventually forcing the downstop bolt through the slat-can wall, puncturing the fuel tank. The leaking fuel ignited upon contact with high-temperature areas on the right engine, leading to the fire and explosions.

Shockingly, the cause of this near-disaster was traced back to a single missing washer, which was found lying just below the opening in the wing forward spar.

In the aftermath of the incident, the Republic of China Civil Aeronautics Administration grounded the entire fleet of Boeing 737-800s operated by China Airlines, Mandarin Airlines, and the Republic of China Air Force for fuel system inspections. The Japanese Civil Aviation Bureau followed suit, requesting inspections of aircraft of the same type operated by Japanese carriers.

Latest News