How NASA’s Biggest Telescope Beat Loose Screws

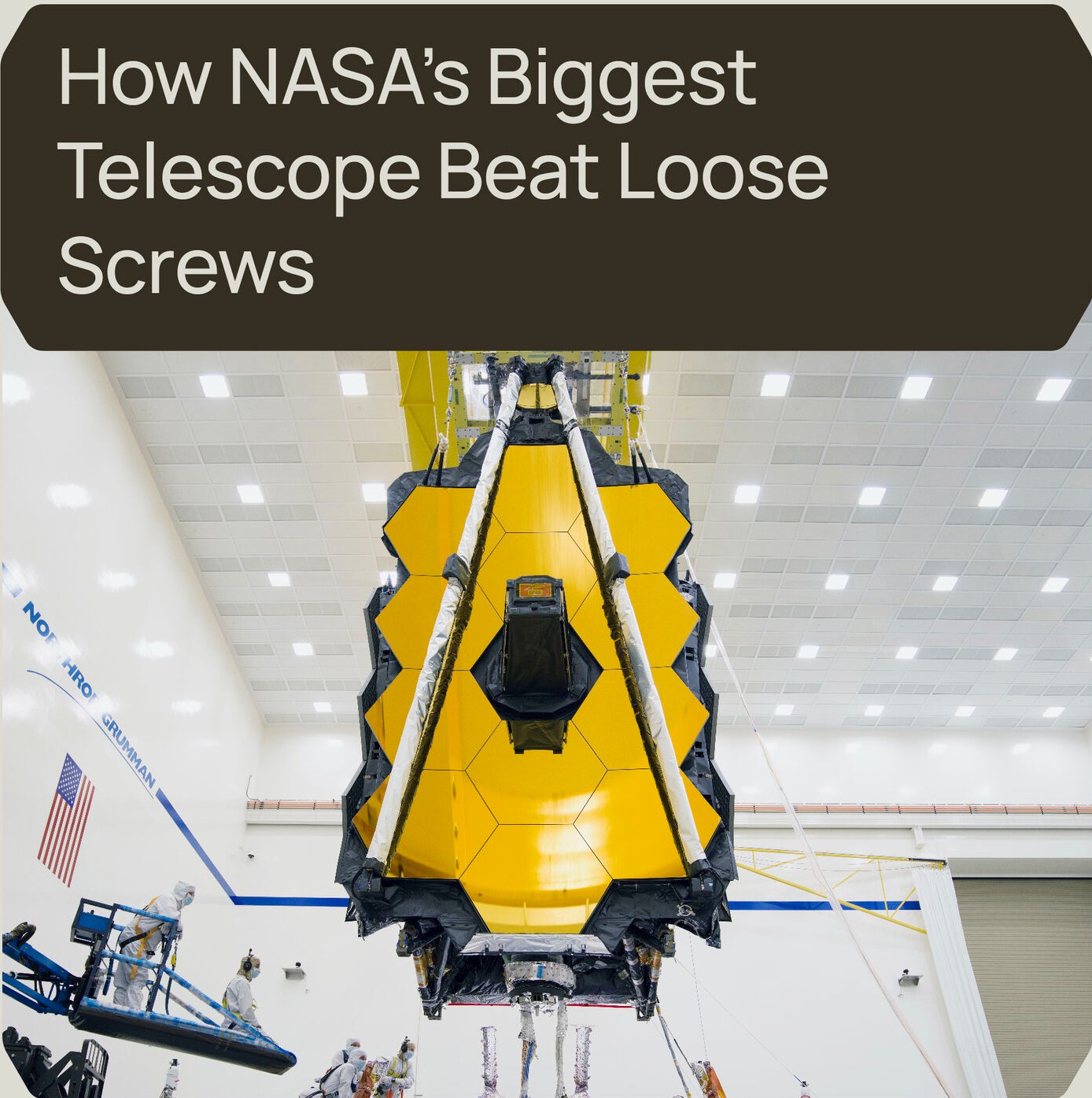

NASA's James Webb Space Telescope 🛰 is a million miles away from Earth, observing the depths of the universe and traveling back in time to the time when stars began to form galaxies.

Its 18 gold-plated mirrors make up a system far more sensitive than that of the Hubble Space Telescope, which has succeeded as humanity's most powerful scientific instrument for studying the formation of the universe and the distant worlds of our 🪐 galaxy.

But Webb, at a cost of about $10 billion, had one of the most problematic development schedules of any other space program, lasting more than two decades and costing several billion dollars more than the original budget—$800 million 💵 of that was partly due... to loose screws. And washers. And nuts.

Technicians discovered that screws fell out during a test-they put the solar shield through a vibration test, simulating vibrations twice as strong as expected during launch. When the test was over, technicians counted 20 loose screws out of the 1,000 needed to secure the thin material covering the solar shield.

These screws, half the thickness of a 🪙 dime, were designed to fit into a safety nut. But the tip of the screws could potentially scratch or tear the solar shield cover. Somewhere in the process, the technicians decided to add a washer to keep the screws from protruding too much. They didn't realize, however, that the washer could prevent them from securing, and some screws were left with one less thread.

While these kinds of problems are not uncommon during testing for complex spacecraft, this error set the project back by a year and a half and cost hundreds of millions of dollars. Whether you're building the next James Webb or not, Tsamouris 🧑🚀 is here to help you with everything, everywhere, every time.

How NASA’s Biggest Telescope Beat Loose Screws

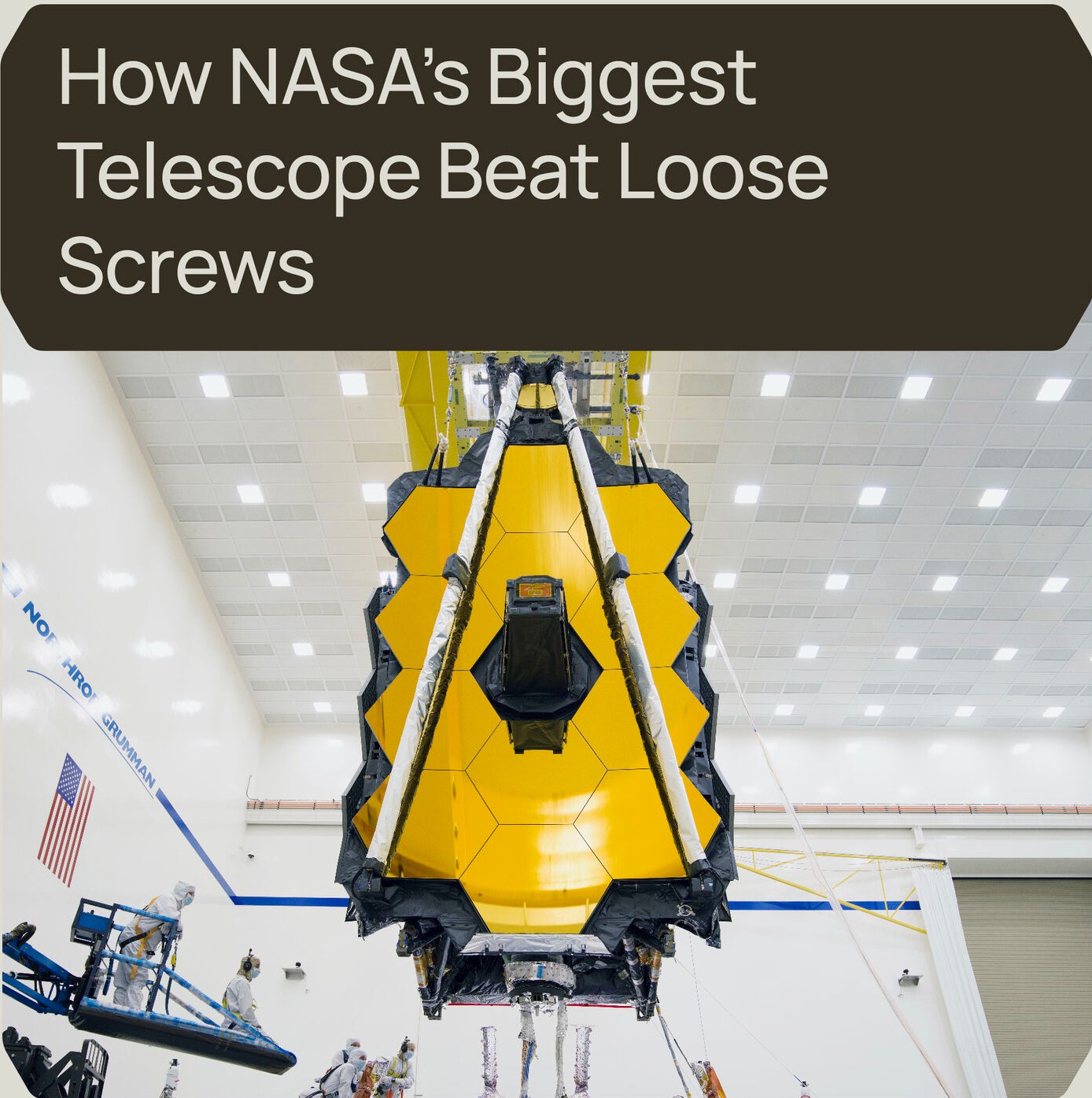

NASA's James Webb Space Telescope 🛰 is a million miles away from Earth, observing the depths of the universe and traveling back in time to the time when stars began to form galaxies.

Its 18 gold-plated mirrors make up a system far more sensitive than that of the Hubble Space Telescope, which has succeeded as humanity's most powerful scientific instrument for studying the formation of the universe and the distant worlds of our 🪐 galaxy.

But Webb, at a cost of about $10 billion, had one of the most problematic development schedules of any other space program, lasting more than two decades and costing several billion dollars more than the original budget—$800 million 💵 of that was partly due... to loose screws. And washers. And nuts.

Technicians discovered that screws fell out during a test-they put the solar shield through a vibration test, simulating vibrations twice as strong as expected during launch. When the test was over, technicians counted 20 loose screws out of the 1,000 needed to secure the thin material covering the solar shield.

These screws, half the thickness of a 🪙 dime, were designed to fit into a safety nut. But the tip of the screws could potentially scratch or tear the solar shield cover. Somewhere in the process, the technicians decided to add a washer to keep the screws from protruding too much. They didn't realize, however, that the washer could prevent them from securing, and some screws were left with one less thread.

While these kinds of problems are not uncommon during testing for complex spacecraft, this error set the project back by a year and a half and cost hundreds of millions of dollars. Whether you're building the next James Webb or not, Tsamouris 🧑🚀 is here to help you with everything, everywhere, every time.

Latest News