How To Size Fasteners Correctly

Often, fasteners have to endure extreme temperatures, vibration, pressure, and shock. This is why choosing the correct size 📐 and material for a fastener is critical. Ideally, you want to select a fastener that will create a clamping force that prevents separation and movement of the clamped parts once external forces are applied.

Unfortunately, often, people oversize the fastener, which can lead to a joint with a low clamp load, high risk for failure, and difficulty tightening. Follow these steps when selecting the appropriate size fastener:

1️⃣ Determine the maximum load that will be placed on the joint

2️⃣ Calculate the clamping force that will be put on the fastener.

3️⃣ Choose the minimum bolt diameter to support that clamp load, ensuring a tight fit.

4️⃣ Secure the bolt effectively, and decide which tightening method would be most appropriate.

If you follow these steps, you can be confident that you are choosing a fastener that is appropriately sized for your needs.

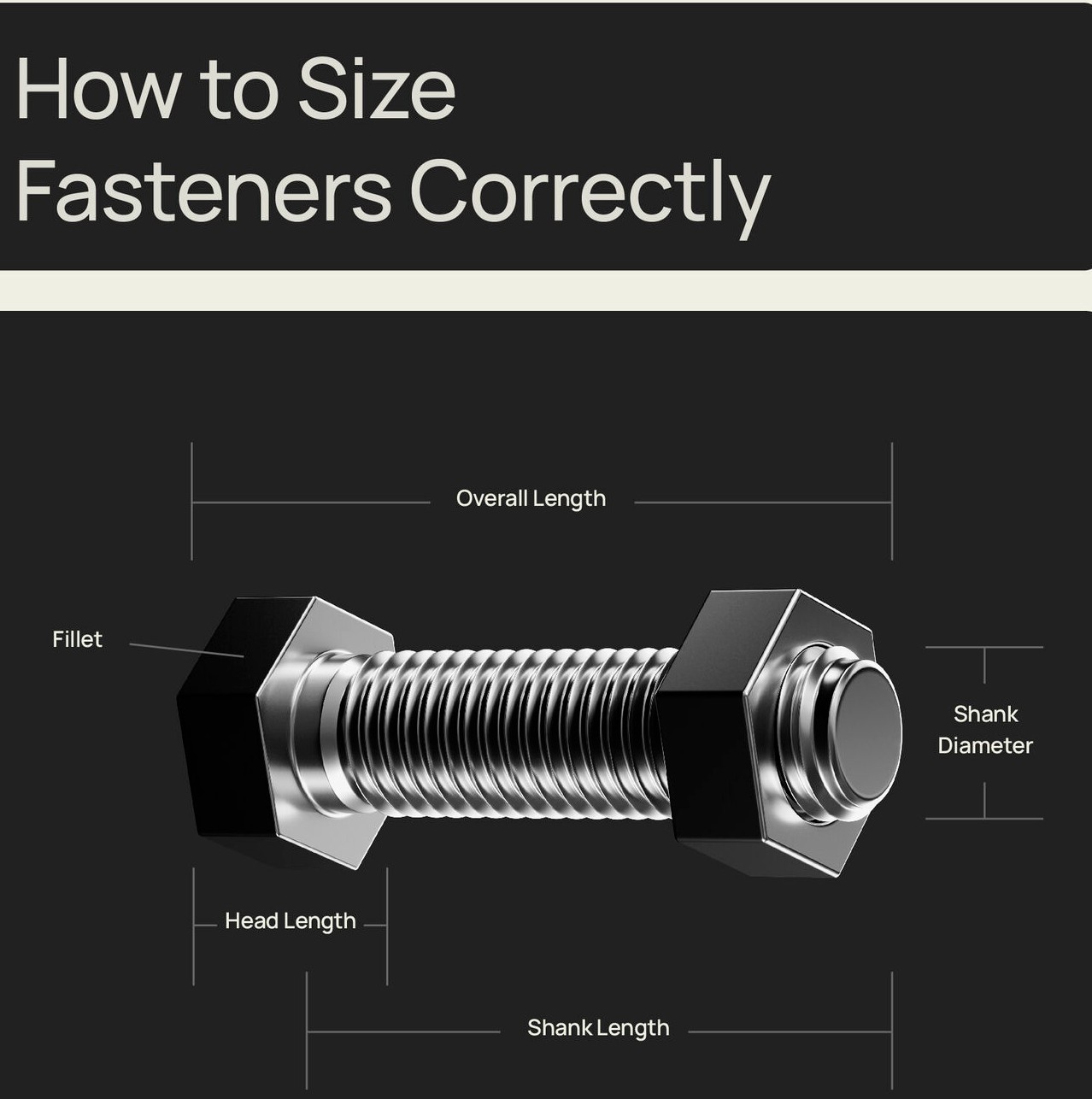

How do you measure fastener size?

While calculating clamping force may be easy in theory, you can use an online 🧮 calculator. You might need to measure the diameter of screws and bolts yourself. To find the major diameter of bolts (the most commonly-used one), you need to measure the distance from the outer thread on one side to the outer thread on the other. This is called the major diameter and will usually be the proper bolt size. You can also measure from the bottom cavity of the threads from one side to the other to find the minor diameter. Different types of screws are measured differently.

If you have a screw that's flat on the bottom (this is the most common type), measure from the bottom of the head to the type. This also applies to hex and hex washer head screws and 🔩 bolts. Self-drilling screws, meanwhile, are measured from the bottom of the head to the end of the drill point tip. Flathead, countersunk screws and oval head screws are usually measured from the point to the tip (the full screw).

Do you not know where to start? We are here to help. So reach out 📟 to us, and we can answer your questions for everything, everywhere, every time.

How To Size Fasteners Correctly

Often, fasteners have to endure extreme temperatures, vibration, pressure, and shock. This is why choosing the correct size 📐 and material for a fastener is critical. Ideally, you want to select a fastener that will create a clamping force that prevents separation and movement of the clamped parts once external forces are applied.

Unfortunately, often, people oversize the fastener, which can lead to a joint with a low clamp load, high risk for failure, and difficulty tightening. Follow these steps when selecting the appropriate size fastener:

1️⃣ Determine the maximum load that will be placed on the joint

2️⃣ Calculate the clamping force that will be put on the fastener.

3️⃣ Choose the minimum bolt diameter to support that clamp load, ensuring a tight fit.

4️⃣ Secure the bolt effectively, and decide which tightening method would be most appropriate.

If you follow these steps, you can be confident that you are choosing a fastener that is appropriately sized for your needs.

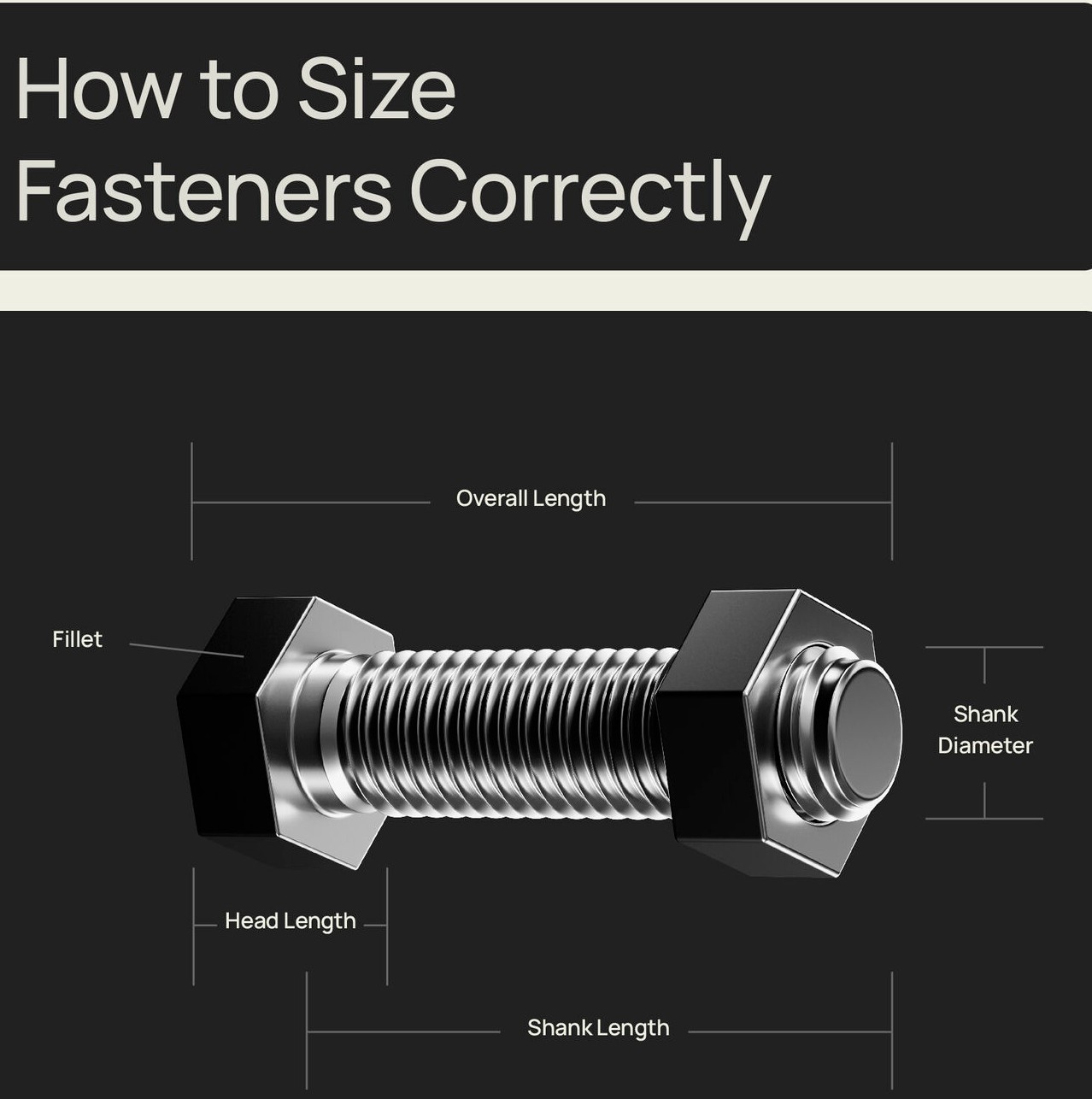

How do you measure fastener size?

While calculating clamping force may be easy in theory, you can use an online 🧮 calculator. You might need to measure the diameter of screws and bolts yourself. To find the major diameter of bolts (the most commonly-used one), you need to measure the distance from the outer thread on one side to the outer thread on the other. This is called the major diameter and will usually be the proper bolt size. You can also measure from the bottom cavity of the threads from one side to the other to find the minor diameter. Different types of screws are measured differently.

If you have a screw that's flat on the bottom (this is the most common type), measure from the bottom of the head to the type. This also applies to hex and hex washer head screws and 🔩 bolts. Self-drilling screws, meanwhile, are measured from the bottom of the head to the end of the drill point tip. Flathead, countersunk screws and oval head screws are usually measured from the point to the tip (the full screw).

Do you not know where to start? We are here to help. So reach out 📟 to us, and we can answer your questions for everything, everywhere, every time.

Latest News