Subsea Oil-Well Bolts Are Failing

Tsamouris, the Fastener Specialists©

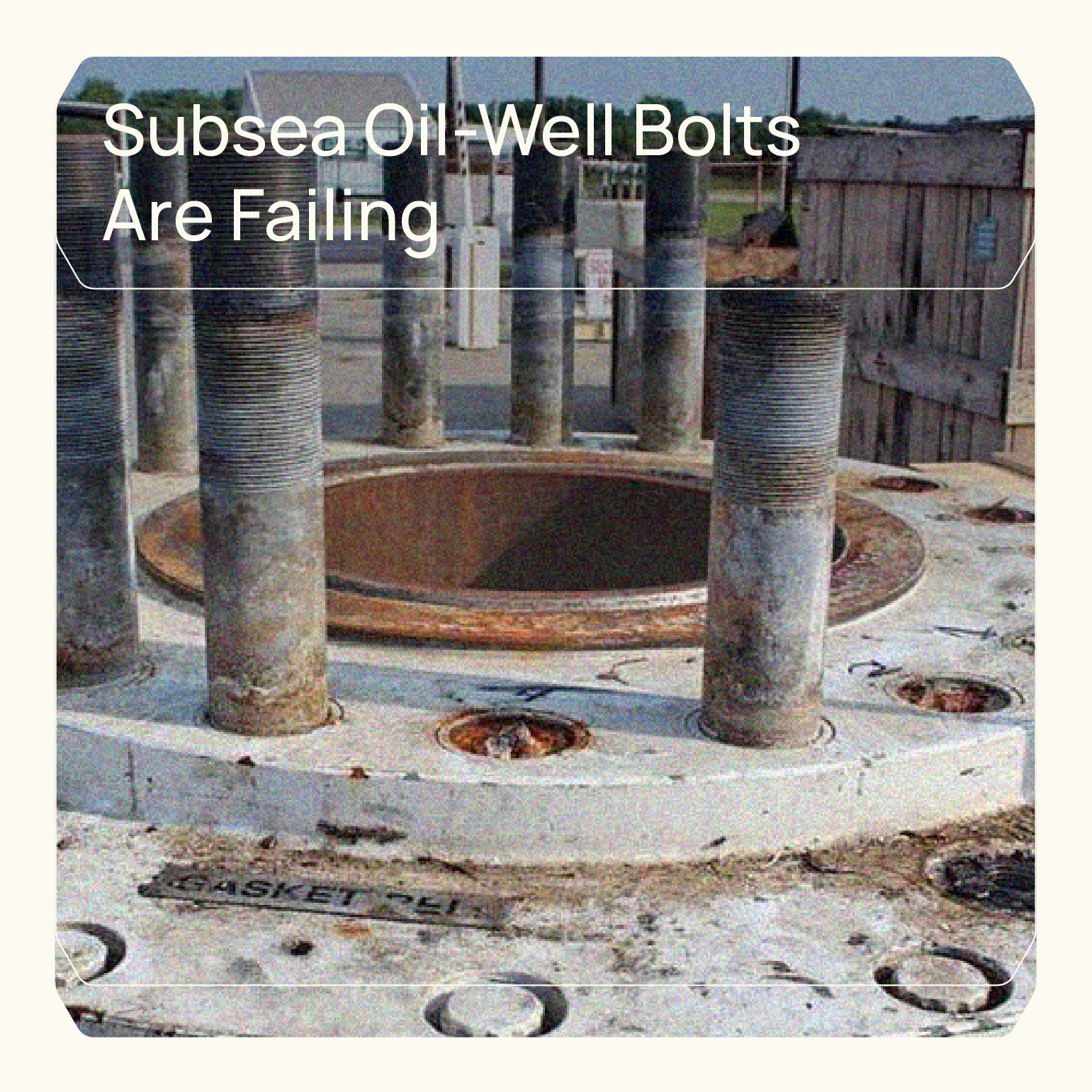

In 2013, the U.S. Department of the Interior (DOI) launched an investigation into the failure of massive bolts that secure subsea oil equipment in the Gulf of Mexico. The inquiry was triggered by a worldwide recall of defective bolts by General Electric Co.'s oil-exploration equipment business, which reported incidents of corrosion and snapping. These failures have led to costly shutdowns and raised serious concerns about the safety of subsea wells.

The potential consequences of bolt failures in subsea oil equipment are severe, as they could lead to major oil leaks with devastating environmental impacts. The 2010 BP oil spill in the Gulf of Mexico, for example, was linked to a record spike in marine animal deaths, particularly among bottlenose dolphins. The spill, which occurred after the BP-owned Deepwater Horizon oil rig exploded, released more than four million barrels of unprocessed oil before being sealed five months later, highlighting the difficulty and expense of cleaning up such disasters.

The DOI's investigation, along with two additional bolt failure incidents, has led industry officials and safety regulators to believe that the problem extends beyond GE and its blowout preventers, which are critical devices used to seal, monitor, and control oil and gas wells. Flaws have also been discovered in bolts manufactured by GE's competitors for similar equipment.

Manufacturers and regulators have identified several potential factors contributing to the bolt failures, including the adequacy of the alloys used in the heavy steel bolts, the appropriateness of the coatings applied to the bolts, and the practice of "over-torquing" by subcontractors, which can weaken the fasteners. GE has acknowledged that over-torquing may have played a role in its bolt failures.

The bolt failures have been traced decades back, and while they have not yet resulted in any oil leaks, regulators consider the issue to be of critical importance. The problem may affect more than 2,400 platforms and oil rigs in the Gulf of Mexico, 23 off the coast of California, and an active rig on the outer continental shelf in Alaska.

As an officer of the Bureau of Safety and Environmental Enforcement stated: ”If your smallest component fails, you can't expect a sophisticated many-million-dollar piece of equipment to prevent a leak.”

In 2013, the U.S. Department of the Interior (DOI) launched an investigation into the failure of massive bolts that secure subsea oil equipment in the Gulf of Mexico. The inquiry was triggered by a worldwide recall of defective bolts by General Electric Co.'s oil-exploration equipment business, which reported incidents of corrosion and snapping. These failures have led to costly shutdowns and raised serious concerns about the safety of subsea wells.

The potential consequences of bolt failures in subsea oil equipment are severe, as they could lead to major oil leaks with devastating environmental impacts. The 2010 BP oil spill in the Gulf of Mexico, for example, was linked to a record spike in marine animal deaths, particularly among bottlenose dolphins. The spill, which occurred after the BP-owned Deepwater Horizon oil rig exploded, released more than four million barrels of unprocessed oil before being sealed five months later, highlighting the difficulty and expense of cleaning up such disasters.

The DOI's investigation, along with two additional bolt failure incidents, has led industry officials and safety regulators to believe that the problem extends beyond GE and its blowout preventers, which are critical devices used to seal, monitor, and control oil and gas wells. Flaws have also been discovered in bolts manufactured by GE's competitors for similar equipment.

Manufacturers and regulators have identified several potential factors contributing to the bolt failures, including the adequacy of the alloys used in the heavy steel bolts, the appropriateness of the coatings applied to the bolts, and the practice of "over-torquing" by subcontractors, which can weaken the fasteners. GE has acknowledged that over-torquing may have played a role in its bolt failures.

The bolt failures have been traced decades back, and while they have not yet resulted in any oil leaks, regulators consider the issue to be of critical importance. The problem may affect more than 2,400 platforms and oil rigs in the Gulf of Mexico, 23 off the coast of California, and an active rig on the outer continental shelf in Alaska.

As an officer of the Bureau of Safety and Environmental Enforcement stated: ”If your smallest component fails, you can't expect a sophisticated many-million-dollar piece of equipment to prevent a leak.”

Subsea Oil-Well Bolts Are Failing

Tsamouris, the Fastener Specialists©

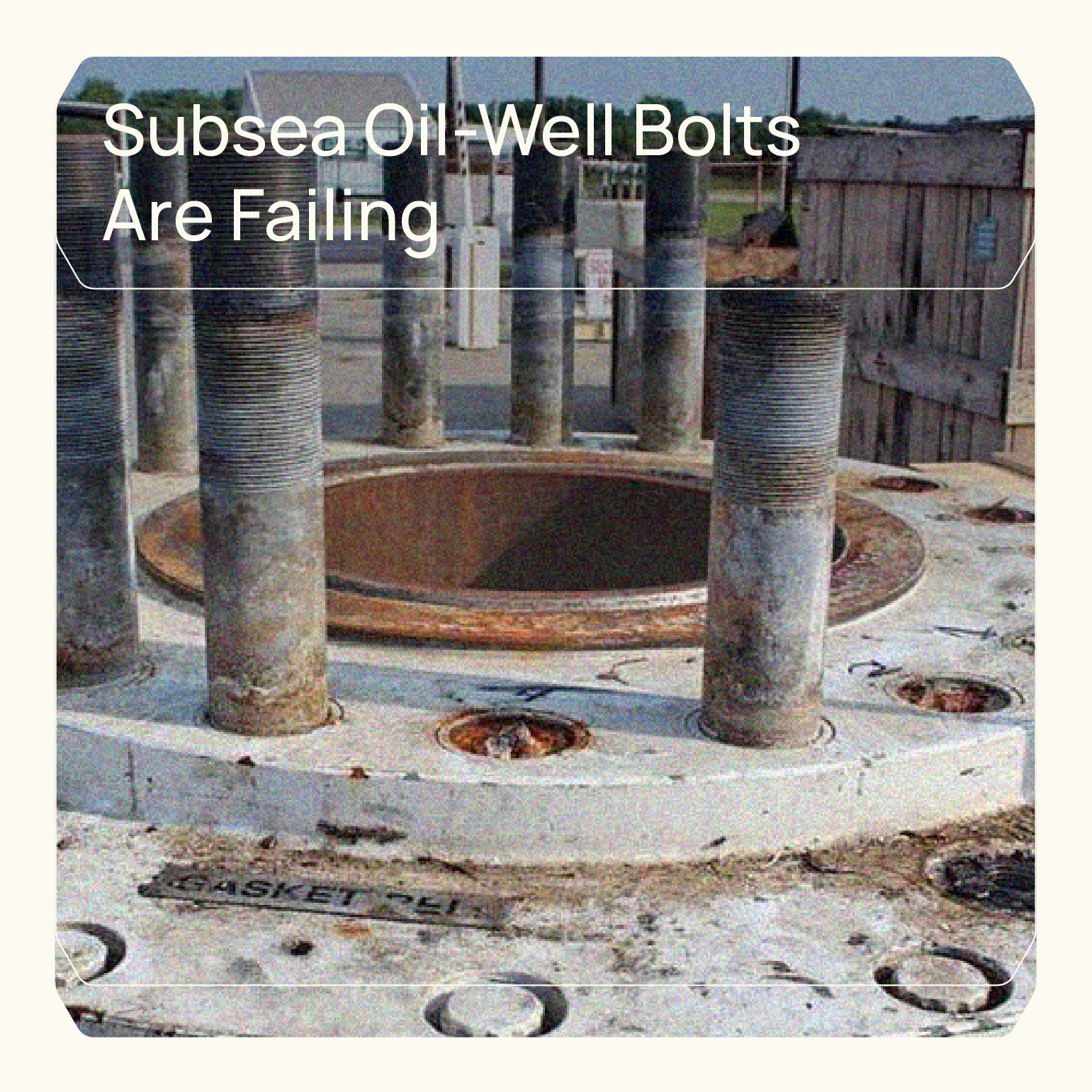

In 2013, the U.S. Department of the Interior (DOI) launched an investigation into the failure of massive bolts that secure subsea oil equipment in the Gulf of Mexico. The inquiry was triggered by a worldwide recall of defective bolts by General Electric Co.'s oil-exploration equipment business, which reported incidents of corrosion and snapping. These failures have led to costly shutdowns and raised serious concerns about the safety of subsea wells.

The potential consequences of bolt failures in subsea oil equipment are severe, as they could lead to major oil leaks with devastating environmental impacts. The 2010 BP oil spill in the Gulf of Mexico, for example, was linked to a record spike in marine animal deaths, particularly among bottlenose dolphins. The spill, which occurred after the BP-owned Deepwater Horizon oil rig exploded, released more than four million barrels of unprocessed oil before being sealed five months later, highlighting the difficulty and expense of cleaning up such disasters.

The DOI's investigation, along with two additional bolt failure incidents, has led industry officials and safety regulators to believe that the problem extends beyond GE and its blowout preventers, which are critical devices used to seal, monitor, and control oil and gas wells. Flaws have also been discovered in bolts manufactured by GE's competitors for similar equipment.

Manufacturers and regulators have identified several potential factors contributing to the bolt failures, including the adequacy of the alloys used in the heavy steel bolts, the appropriateness of the coatings applied to the bolts, and the practice of "over-torquing" by subcontractors, which can weaken the fasteners. GE has acknowledged that over-torquing may have played a role in its bolt failures.

The bolt failures have been traced decades back, and while they have not yet resulted in any oil leaks, regulators consider the issue to be of critical importance. The problem may affect more than 2,400 platforms and oil rigs in the Gulf of Mexico, 23 off the coast of California, and an active rig on the outer continental shelf in Alaska.

As an officer of the Bureau of Safety and Environmental Enforcement stated: ”If your smallest component fails, you can't expect a sophisticated many-million-dollar piece of equipment to prevent a leak.”

In 2013, the U.S. Department of the Interior (DOI) launched an investigation into the failure of massive bolts that secure subsea oil equipment in the Gulf of Mexico. The inquiry was triggered by a worldwide recall of defective bolts by General Electric Co.'s oil-exploration equipment business, which reported incidents of corrosion and snapping. These failures have led to costly shutdowns and raised serious concerns about the safety of subsea wells.

The potential consequences of bolt failures in subsea oil equipment are severe, as they could lead to major oil leaks with devastating environmental impacts. The 2010 BP oil spill in the Gulf of Mexico, for example, was linked to a record spike in marine animal deaths, particularly among bottlenose dolphins. The spill, which occurred after the BP-owned Deepwater Horizon oil rig exploded, released more than four million barrels of unprocessed oil before being sealed five months later, highlighting the difficulty and expense of cleaning up such disasters.

The DOI's investigation, along with two additional bolt failure incidents, has led industry officials and safety regulators to believe that the problem extends beyond GE and its blowout preventers, which are critical devices used to seal, monitor, and control oil and gas wells. Flaws have also been discovered in bolts manufactured by GE's competitors for similar equipment.

Manufacturers and regulators have identified several potential factors contributing to the bolt failures, including the adequacy of the alloys used in the heavy steel bolts, the appropriateness of the coatings applied to the bolts, and the practice of "over-torquing" by subcontractors, which can weaken the fasteners. GE has acknowledged that over-torquing may have played a role in its bolt failures.

The bolt failures have been traced decades back, and while they have not yet resulted in any oil leaks, regulators consider the issue to be of critical importance. The problem may affect more than 2,400 platforms and oil rigs in the Gulf of Mexico, 23 off the coast of California, and an active rig on the outer continental shelf in Alaska.

As an officer of the Bureau of Safety and Environmental Enforcement stated: ”If your smallest component fails, you can't expect a sophisticated many-million-dollar piece of equipment to prevent a leak.”

Latest News