What Are Electroplated Fasteners

🔋 Electroplated fasteners are fasteners that are coated with a thin layer of metal using an electroplating process. This metal coating provides a barrier against corrosion and wear and can also improve the appearance of the fastener.

There are many different metals that can be used for electroplating, including copper, nickel, and chromium. The type of metal used will depend on the intended application of the fastener. For example, chromium is often used for fasteners that will be exposed to 🌡 high temperatures, while nickel is often used for fasteners that need to be resistant to corrosion.

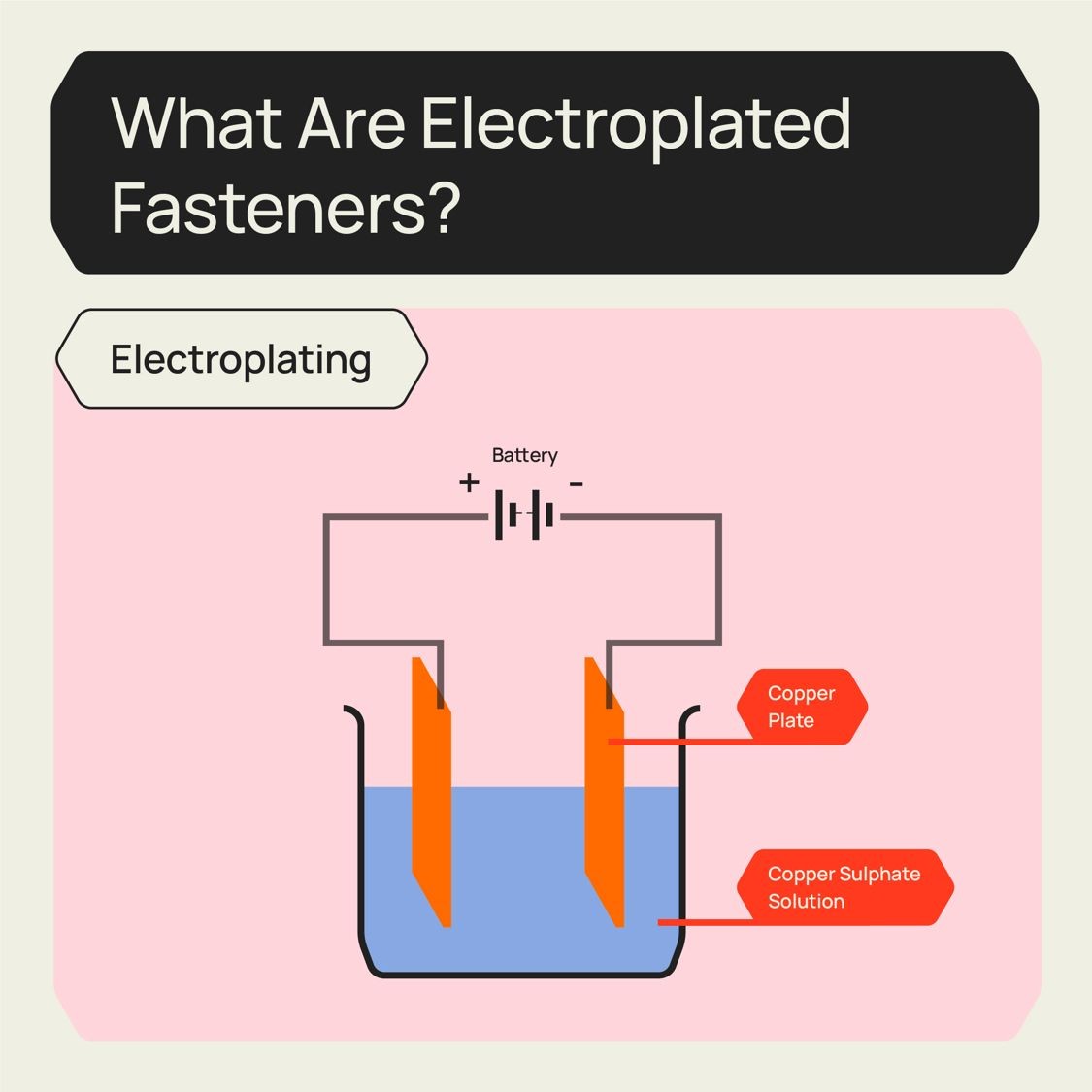

The electroplating process is relatively simple. First, the metal that will be used for electroplating is dissolved in a solution. Then, an electric current is passed through the solution, causing the metal to deposit onto the surface of the fastener. The thickness of the metal coating can be controlled by adjusting the electric current, the concentration of the metal solution, or the amount of time the fastener is left in the 🧪 solution. Once the desired thickness is achieved, the fastener is removed from the solution and allowed to dry.

Electroplated fasteners are used in a variety of applications, including automotive, plumbing, and electronics. They are especially well-suited for applications where corrosion resistance is important.

Got 📮 questions? We’re here to help. Be it through text or live call, we’re here for everything, everywhere, every time.

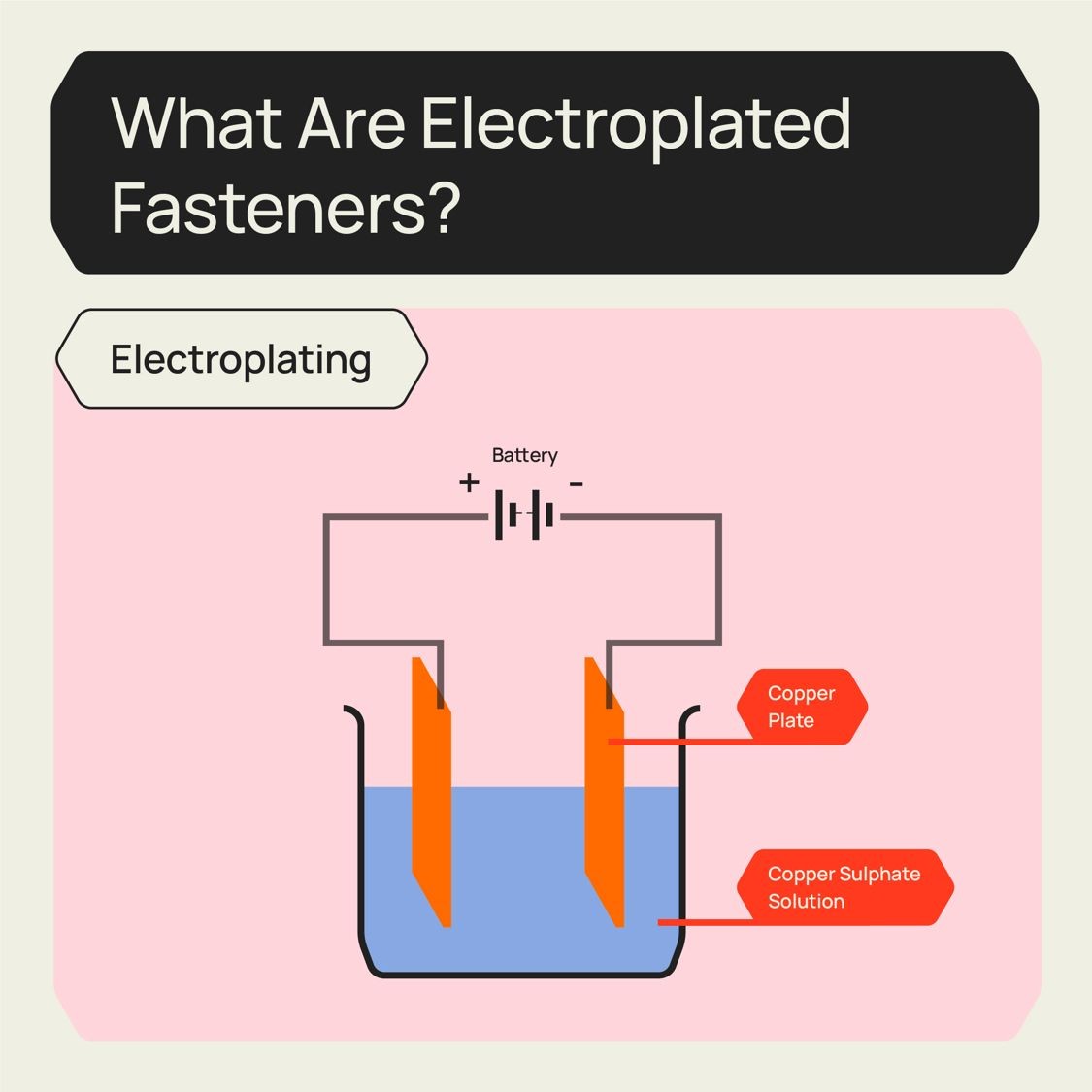

What Are Electroplated Fasteners

🔋 Electroplated fasteners are fasteners that are coated with a thin layer of metal using an electroplating process. This metal coating provides a barrier against corrosion and wear and can also improve the appearance of the fastener.

There are many different metals that can be used for electroplating, including copper, nickel, and chromium. The type of metal used will depend on the intended application of the fastener. For example, chromium is often used for fasteners that will be exposed to 🌡 high temperatures, while nickel is often used for fasteners that need to be resistant to corrosion.

The electroplating process is relatively simple. First, the metal that will be used for electroplating is dissolved in a solution. Then, an electric current is passed through the solution, causing the metal to deposit onto the surface of the fastener. The thickness of the metal coating can be controlled by adjusting the electric current, the concentration of the metal solution, or the amount of time the fastener is left in the 🧪 solution. Once the desired thickness is achieved, the fastener is removed from the solution and allowed to dry.

Electroplated fasteners are used in a variety of applications, including automotive, plumbing, and electronics. They are especially well-suited for applications where corrosion resistance is important.

Got 📮 questions? We’re here to help. Be it through text or live call, we’re here for everything, everywhere, every time.

Latest News