Tsamouris, the Fastener Specialists©

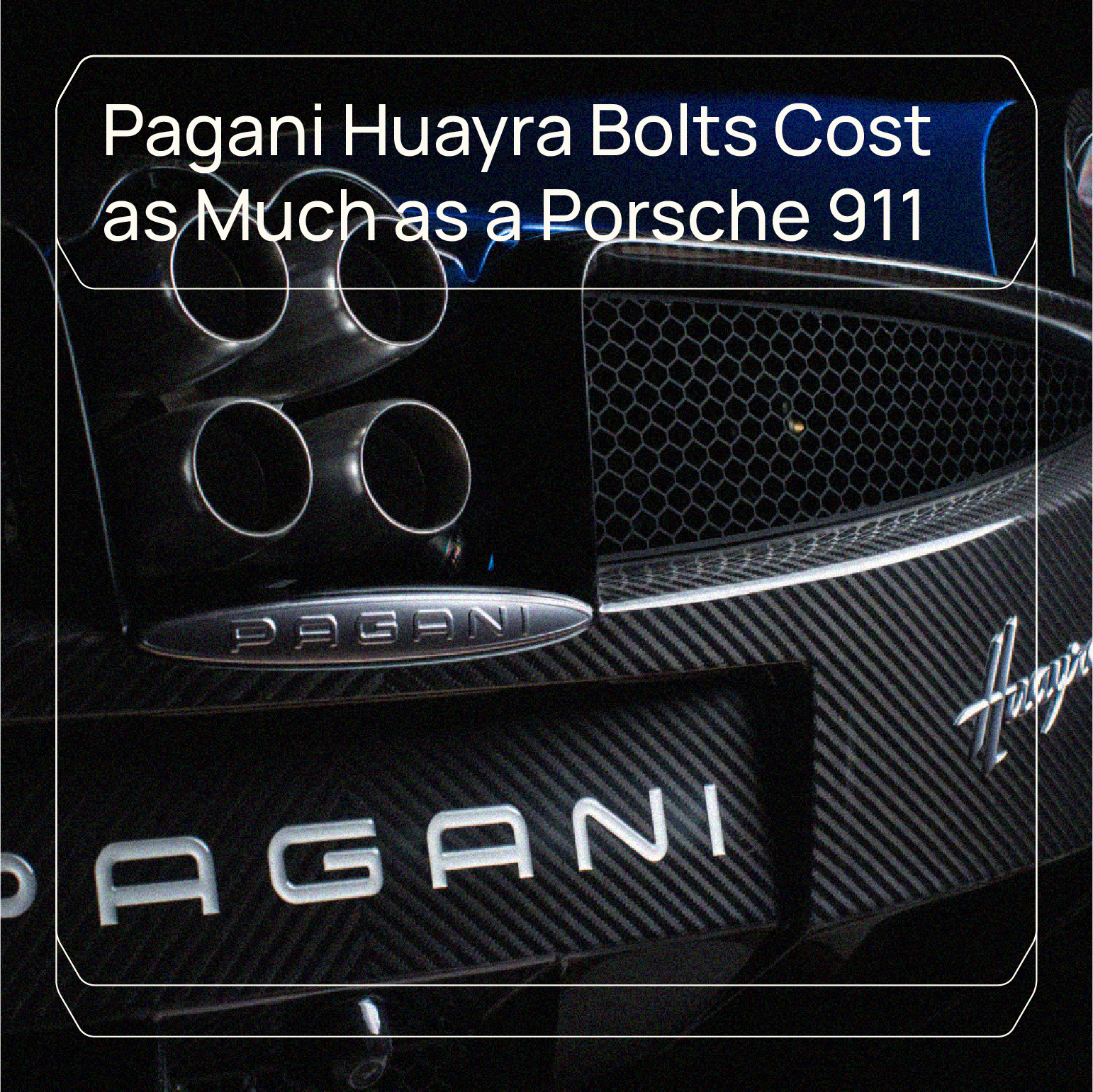

Pagani’s flagship hypercar, the Huayra, is a true marvel of engineering, boasting a powerful AMG-sourced

V12 engine and stunning design. But it’s the car’s 1,400 unique titanium bolts that truly showcase the

brand’s obsessive attention to detail.

Each bolt, made from grade 7 Titanium with added palladium for enhanced corrosion resistance, is

individually engraved with the Pagani logo. This level of craftsmanship comes at a price: a single bolt costs

around USD 95 (EUR 88), meaning the Huayra’s bolts alone are worth a staggering USD 133,000 (EUR

123,000) – enough to buy a brand new Porsche 911.

Pagani’s choice of high-quality, lightweight materials like Titanium ensures the Huayra can withstand the

rigors of high-performance driving while maintaining its impeccable aesthetics. The engraved bolts serve as

a subtle yet powerful reminder of the brand’s uncompromising commitment to excellence.

At Tsamouris, we share Pagani’s dedication to providing customers with fasteners that meet the highest

standards of strength, durability, and reliability. Discover our range of top-quality fasteners, the go-to choice

for Greece’s leading construction and industrial groups.