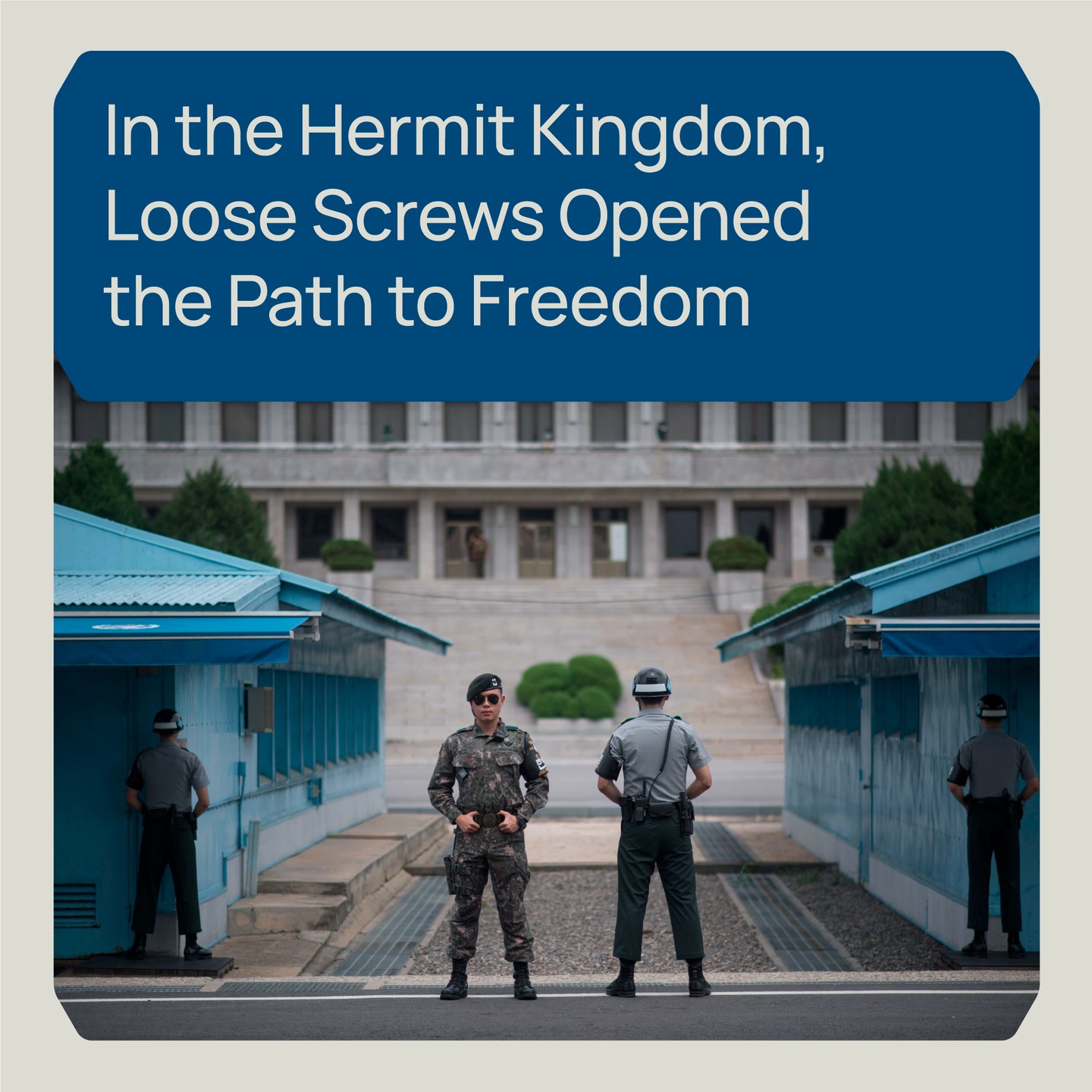

A border bristling with soldiers, where every step could be your last because of mines and fences sharp enough to slice the sky. This is the DMZ, a no-man’s-land splitting the Korean Peninsula into North and South.

Yet, in a twist that seems more like a scene from a suspense film, a North Korean man made it across — silently, unexpectedly, inexplicably. He was a former gymnast, they say, who used his skills to scale the formidable fence.

And then, the unbelievable part: the high-tech alarms, South Korea’s electronic eyes on the border, didn’t make a sound. The South’s military, faced with embarrassment, had to admit the breach. It turned out the culprit was a few loose screws — quite literally — in the sensor system, a flaw no one saw coming.

The tale begins on a crisp November morning when the man, whose life until then had played out under the watchful gaze of the North’s regime, decided to make a break for freedom. He crawled over that fence, and the alarms stayed silent, giving him a free path to a new life. South Korea’s soldiers, trained for the opposite of silence at this border, scrambled. The hunt was on.

How did he slip by? It was only later they found the sensors, their screws undone — a tiny oversight with enormous consequences. For a country that prides itself on vigilance against its unpredictable neighbor, this was more than a mishap; it was a moment of reckoning.

Questions flew like shrapnel: How could this happen? Who’s accountable? Can we make sure it never happens again? The military’s cheeks weren’t the only things burning. Their phones were, too, with calls for an explanation. They assured the public that every sensor is now under scrutiny, every screw tightened, every eye wide open.

This gymnast’s leap to liberty was rare, almost unheard of. Most who flee North Korea take a longer, no less perilous path through China. Yet, this man’s silent journey across the DMZ, under the moon’s watchful eye, is a stark reminder — sometimes, freedom’s call is so strong it can turn the world’s most dangerous borders into mere hurdles.

As South Korea tightens its screws, we’re reminded of the importance of the binding material in security and the fierce determination of the human spirit. One man’s dash to freedom underscores the countless untold stories still waiting on the other side of the fence.