Tsamouris, the Fastener Specialists©

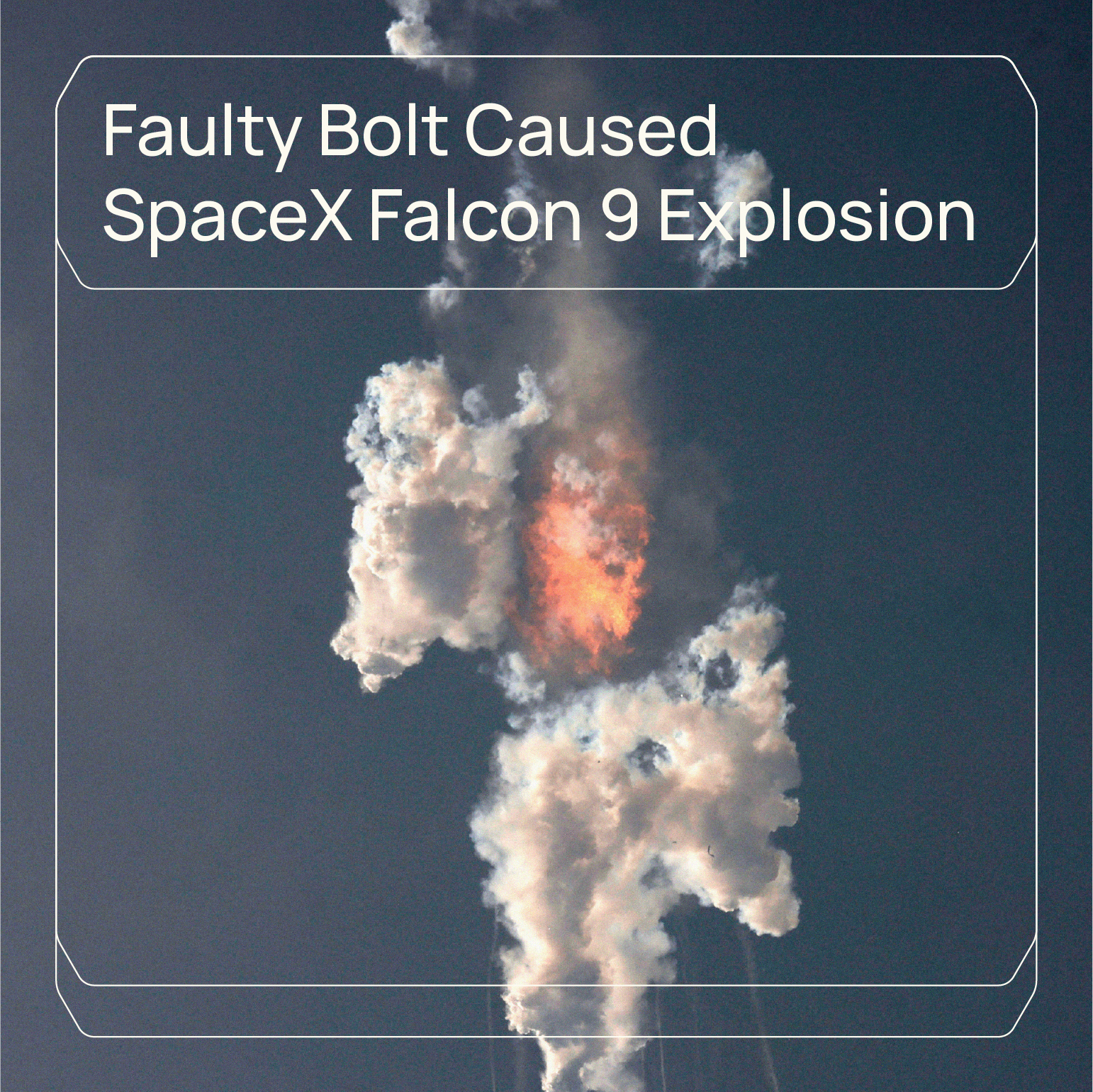

A NASA investigation into the June 2015 SpaceX Falcon 9 rocket failure has concluded that a single bolt,

rather than a manufacturing defect, was behind the catastrophic event.

The unmanned mission, known as CRS-7, was supposed to deliver a Dragon cargo spacecraft to the

International Space Station when disaster struck just 139 seconds after liftoff. The rocket’s second stage

liquid oxygen tank suffered an “anomalous event,” causing the vehicle to disintegrate in the blink of an eye.

While SpaceX’s own investigation pointed to a faulty rod end bolt that broke due to a material defect, freeing

a helium-filled composite overwrapped pressure vessel (COPV) to wreak havoc, NASA’s independent review

team found the evidence less conclusive. They suggested that manufacturing damage, improper installation,

or other equally plausible scenarios could have led to the bolt’s failure.

However, the NASA probe went a step further, identifying a critical design flaw: the use of industrial grade

instead of aerospace grade stainless steel for the rod end. This material choice, which lacked proper

modeling and testing for the application, fell short of the manufacturer’s recommended 4:1 safety factor.

The report also highlighted other issues, such as the potential for increased latency in the rocket’s telemetry

system and the risks associated with using commercial parts in flight-critical applications. NASA urged

SpaceX to pay closer attention to manufacturers’ recommendations when sourcing components for their

vehicles.

In response, SpaceX maintained that all credible causes, including those identified by NASA, were

addressed before the Falcon 9’s return to flight.

As a the Fasteners Specialists©, Tsamouris is committed to quality and adherence to the highest standards

to help prevent bolt oversights that could lead to catastrophic failures.