Tsamouris, the Fastener Specialists©

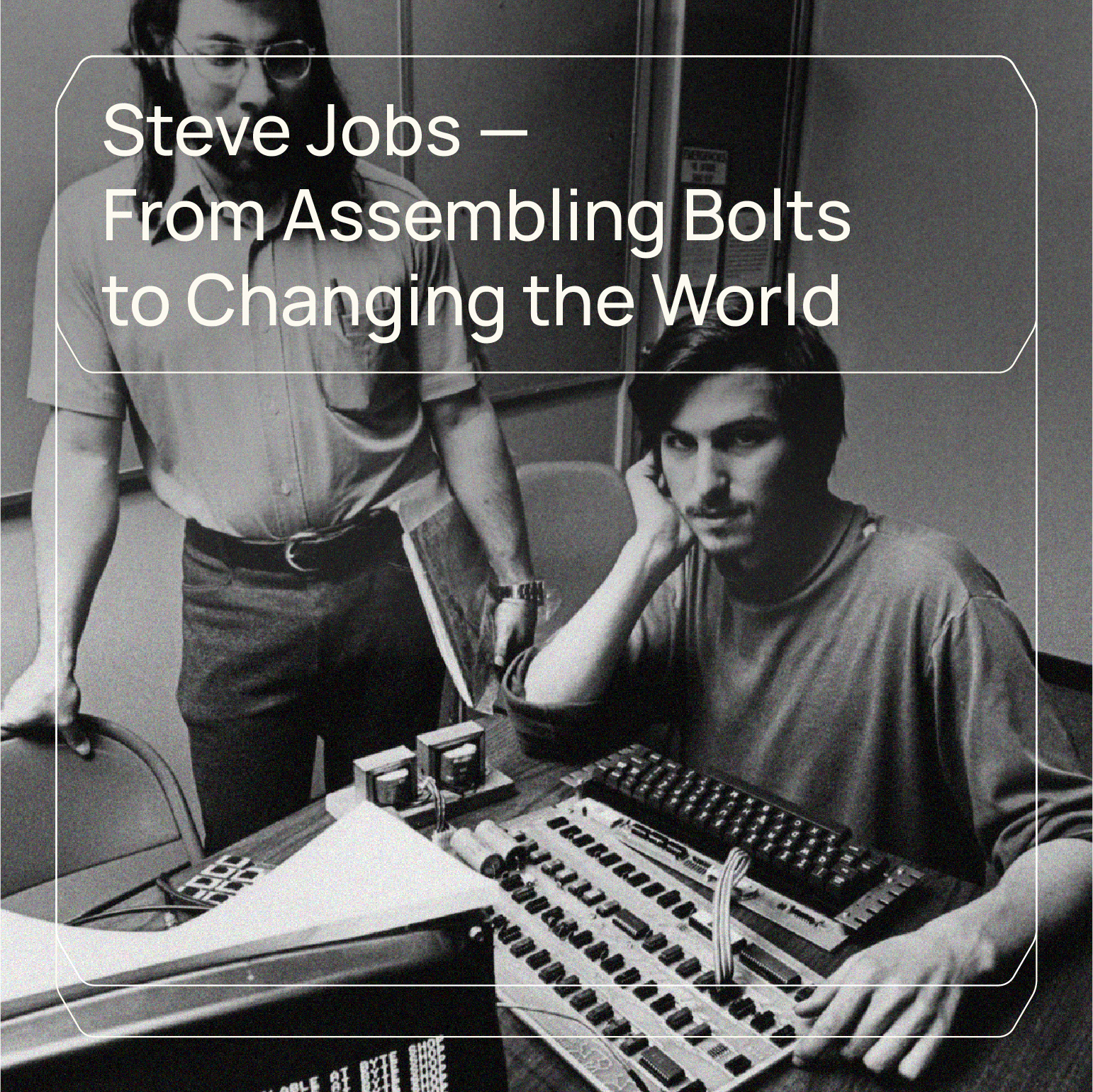

At just 12 years old, Steve Jobs displayed the tenacity and curiosity that would later define his iconic career.

Living in Mountain View, California, Jobs took a bold step that would change his life forever: he cold-called

Hewlett-Packard’s co-founder Bill Hewlett, hoping to secure some leftover electronic parts.

To Jobs’ surprise, Hewlett not only answered the phone but also took the young man’s request seriously.

Amused and impressed by Jobs’ initiative, Hewlett offered him an internship at Hewlett-Packard, where Jobs

spent the summer working on the assembly line, putting nuts and bolts together on frequency counters.

“He got me a job in the place that built them and I was in heaven,”

Jobs recalled in a 1994 interview. This

early experience exposed Jobs to the world of electronics and manufacturing, planting the seeds for his

future endeavors.

Jobs’ story serves as a powerful reminder of the importance of asking for help and seizing opportunities. “I’ve

always found something to be very true, which is most people don’t get those experiences because they

never ask,” he said. “I’ve never found anybody that didn’t want to help me if I asked them for help.”

This philosophy of asking for assistance and being unafraid to reach out to others would become a hallmark

of Jobs’ approach to life and business. It was this same boldness and determination that led him to co-found

Apple, revolutionize the personal computer industry, and transform the way we interact with technology.

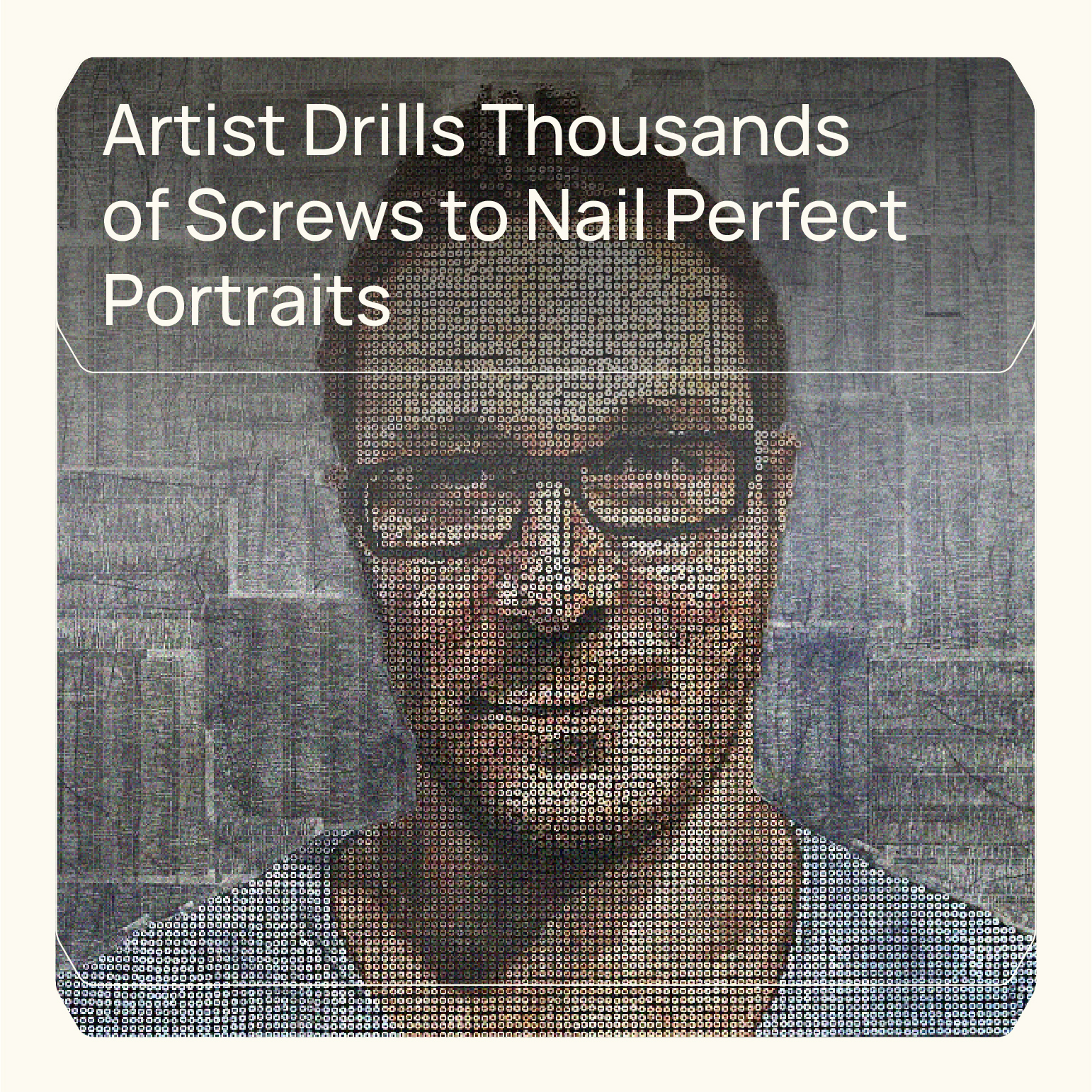

At Tsamouris, we draw inspiration from visionaries like Steve Jobs, who demonstrate the power of curiosity,

initiative, and the willingness to ask for help. Just as Jobs’ early experiences with assembling bolts and

electronic components laid the foundation for his future success, we understand that every component, no

matter how small, contributes to the development of innovative solutions and groundbreaking technologies.