Tsamouris, the Fastener Specialists©

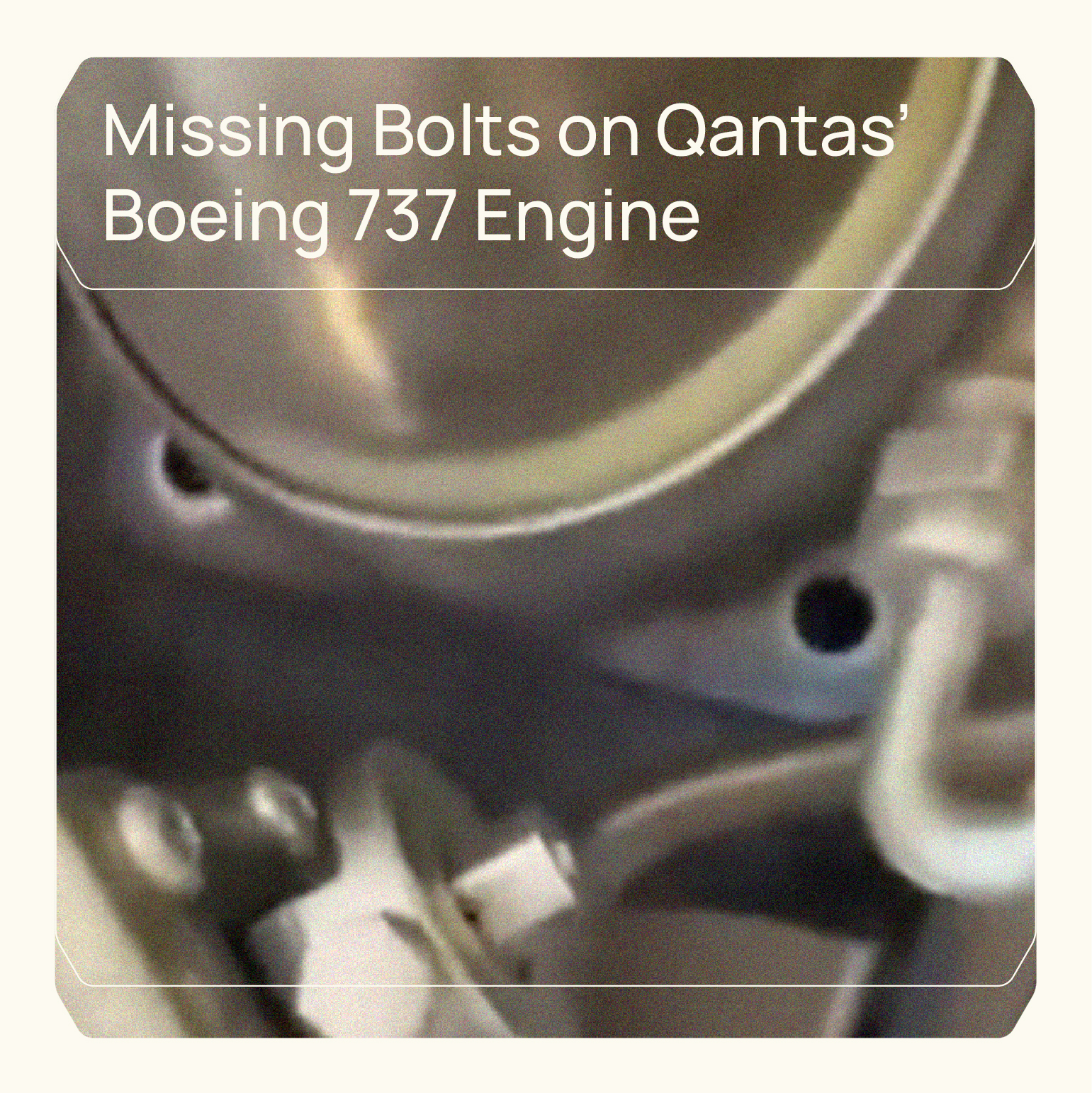

A pilot with the Australian airline Qantas raised concerns about the airline’s maintenance standards after

sharing shocking footage of a Boeing 737 plane missing three out of four bolts and a seal on an engine air

duct. The video, tweeted by journalist Michael West in September 2023, showed that the missing pieces had

fallen into the plane’s cowl.

According to West, the maintenance work on the plane was carried out in Brisbane, and the issue was

identified by engineers on a Saturday. While the missing bolts could have potentially led to a fire onboard,

West admitted that suggesting the plane could have crashed would be too alarmist.

Qantas stated that safety had always been their top priority and that an investigation was underway to

determine how the defects occurred. The airline also emphasized that the air duct takes air away from the

engine and does not impact its operation.

West has raised concerns about Qantas’ cost-cutting measures and outsourcing, suggesting that these

factors may be contributing to mounting problems with the airline’s planes. He also pointed out that

regulators inspect Qantas planes before takeoff to ensure their safety.