Tsamouris, the Fastener Specialists©

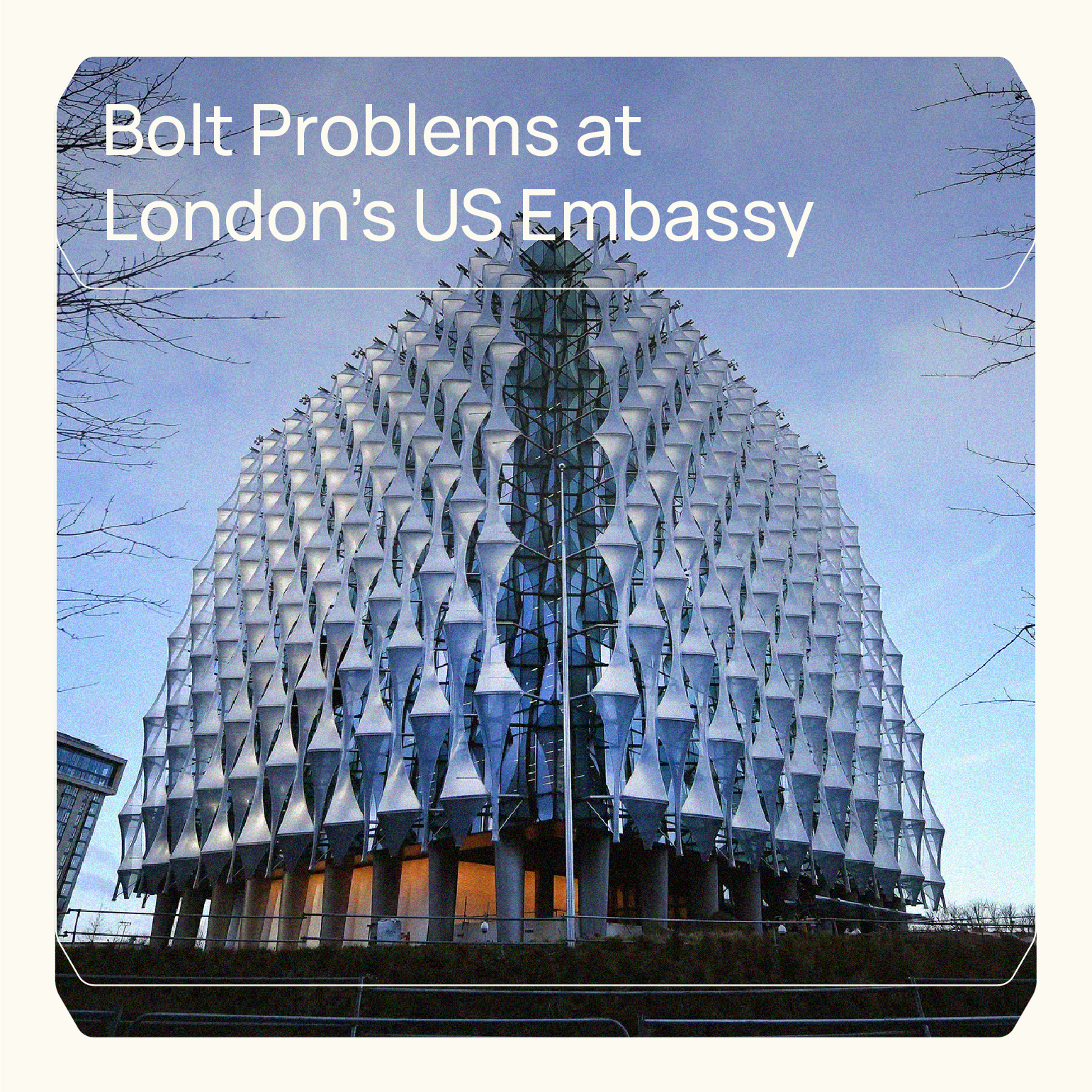

In 2015, thousands of bolts on the new US embassy in Vauxhall, London, needed replacement after some of

them were found faulty.

The GBP 800 million (USD 1 billion or EUR 940 million) cube-shaped embassy, America’s largest in the

Western world, was shrouded in secrecy due to its highly sensitive nature. While details remained scarce, it

was understood that the issues involved bolts on the building’s upper floors.

The steel company tasked with replacing the bolts was the same contractor that had to spend over 6 million

GBP (7.6 million USD or 7.5 million EUR) in 2014, when two of its bolts, each the size of a human arm, broke

on the 738 feet tall (225 meters) “Cheesegrater” skyscraper.

The steel company tasked with replacing the bolts at the embassy was the same one that had to spend over

6 million GBP (7.6 million USD or 7.5 million EUR) in 2014. At that time, three of the bolts it had installed in

the 738-foot (225-meter) “Cheesegrater” skyscraper in London, each the size of a human arm, broke, forcing

the contractor to replace all 3,000 bolts in the skyscraper. Thankfully, no one was injured.

An investigation into the “Cheesegrater” bolt failures revealed that they had fractured due to hydrogen

embrittlement, a process in which hydrogen atoms diffuse into a substance, combine, and create internal

pressure, causing the metal to weaken.

In an era where the complexity and scale of architectural projects continue to grow, the need for fastening

solutions that can withstand the test of time and the elements has never been more crucial.