Tsamouris, the Fastener Specialists©

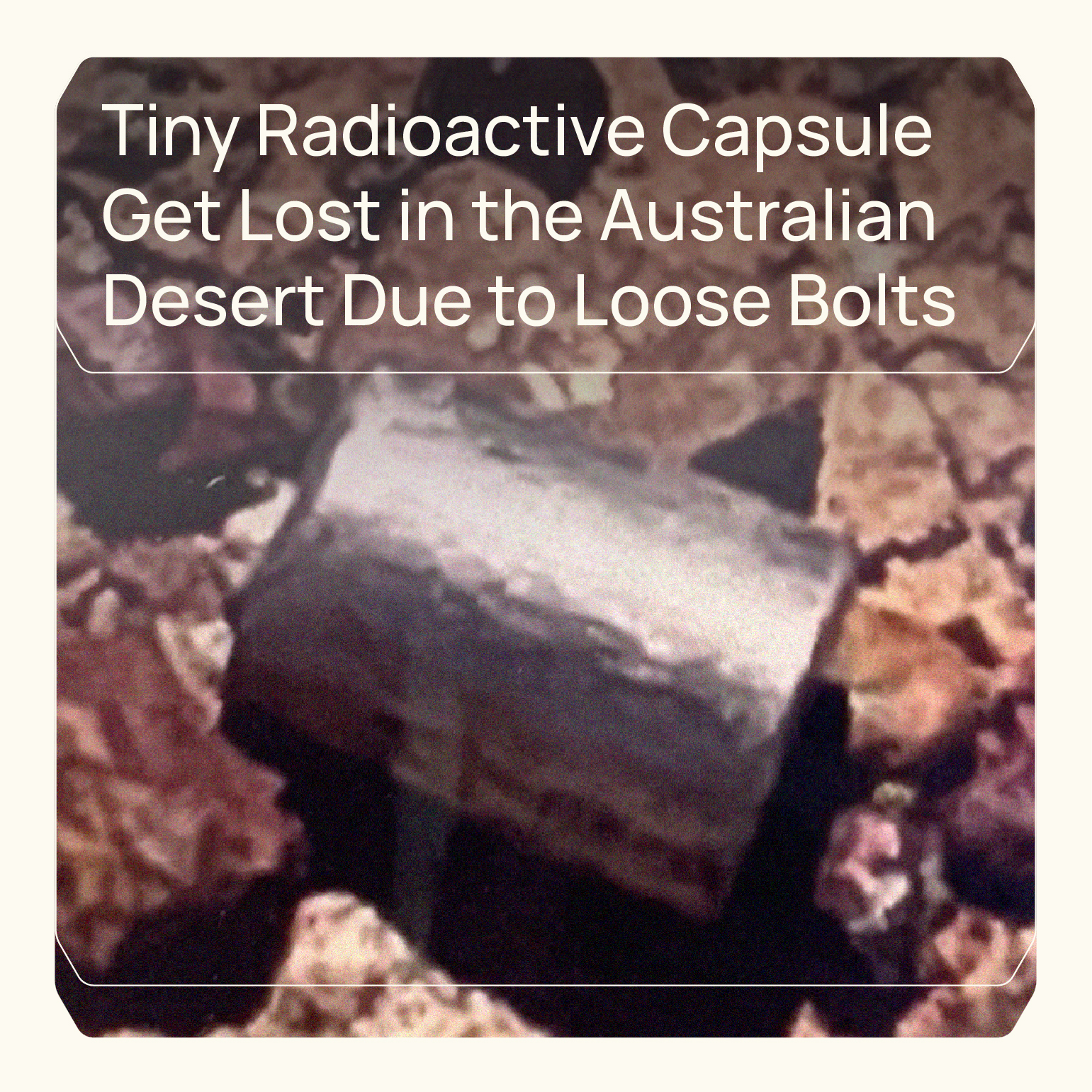

Seeking a Needle in a Haystack? A tiny capsule, no larger than a penny, managed to cause a stir that

reverberated across Australia. This was no ordinary capsule; it was a highly radioactive Caesium-137 device,

used as part of a sensor in mining operations by the giant Rio Tinto. When the capsule went missing in

January 2023, somewhere along a 870-mile (1,400 kilometers) stretch of desert highway, authorities found

themselves in a race against time to locate the potentially lethal object.

The capsule had fallen off the back of a truck during its journey from a mine near the remote town of

Newman to the state capital, Perth. It is believed a bolt securing the lead-lined gauge containing the capsule

worked loose somewhere on the journey – potentially shaken loose by the vibrations of the truck – and the

capsule fell through a hole left by the missing bolt.

The severity of the situation quickly became apparent: a mere hour of exposure at a distance of one meter

was equivalent to receiving ten X-rays, and prolonged contact could lead to skin burns, acute radiation

sickness, and even cancer.

Faced with the daunting task of finding a needle in a haystack, or in this case, a minuscule radioactive

capsule in the vast Outback, authorities deployed specialized radiation detectors to locate the gamma rays

emitted by the device. Search teams meticulously combed the truck’s GPS route, with a particular focus on

the densely populated areas near Perth.

As the days turned into weeks without any sign of the capsule, the urgency of the situation grew. The federal

government stepped in, providing additional resources such as radiation portal monitors and gamma-ray

spectrometers to aid in the search. The hunt for the missing capsule had become a national priority, with the

safety of the public hanging in the balance.

Just as hope began to wane, a breakthrough occurred on February 1st. A vehicle equipped with specialized

detection equipment picked up traces of radiation while traveling at 44 mph (70 km/h) along the search

route. Portable detectors were swiftly deployed, and the capsule was pinpointed a mere two meters off the

side of the road.

Remarkably, it appeared that the capsule had not caused any harm during its time in the wilderness, having

seemingly remained undisturbed where it had initially fallen. An investigation was immediately launched by

the chair of Australia’s Radiological Council to determine how such a dangerous object could have been

misplaced, with the possibility of charges being laid against Rio Tinto.

The case of the missing radioactive capsule serves as a stark reminder of the importance of proper handling

and transportation of even the smallest, most unassuming objects when they possess the potential for harm.