Tsamouris, the Fastener Specialists©

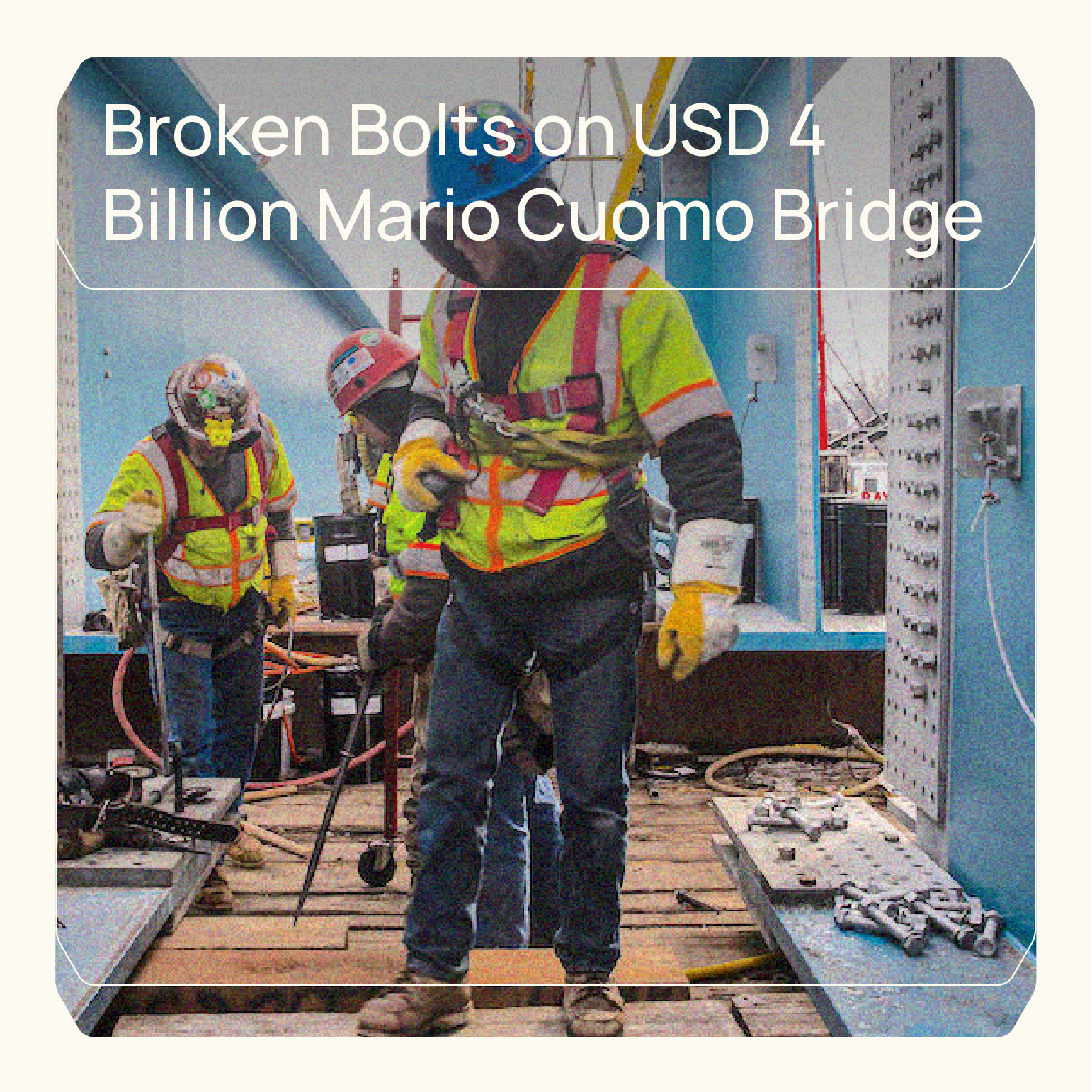

New York’s USD 3.9 billion (EUR 3.6 billion) Mario Cuomo Bridge has been mired in controversy since its

opening in 2017, with allegations of faulty bolts and a potential cover-up by the construction consortium,

Tappan Zee Constructors (TZC). Despite assurances from TZC and the New York Thruway Authority that the

bridge is safe, concerns persist about the structural integrity of the span.

In 2018, a whistleblower claimed that engineers secretly replaced failing bolts to hide the faults from

inspectors. The New York attorney general’s office launched an investigation into the alleged 60 failed bolts

out of the more than one million used in the bridge’s construction.

TZC maintains that all bolt testing indicates no issues and that the bridge is completely safe for the traveling

public. The company spent over USD 1 million (EUR 921,000) on expert assessments and testing,

concluding that a small percentage of bolts had manufacturing defects that led to breakage during

tightening.

In 2021, a federal review by the Federal Highway Administration found “no safety concerns” with the bridge,

according to the Thruway Authority. However, an outside bridge expert cited in a report by The Albany Times

Union called the volume of bolt failures “unprecedented and highly alarming.”

Despite the controversy, TZC stresses that the bridge was built with numerous redundancies to prevent a

collapse, even if some bolts were to fail. The most recent inspection found only one failed bolt out of

hundreds of thousands.