Tsamouris, the Fastener Specialists©

“The Eagle has landed.”

The primary objective of Apollo 11 mission was to complete a national goal set by President John F. Kennedy

on May 25, 1961: perform a crewed lunar landing and return to Earth.

Apollo 11 launched from Cape Kennedy on July 16, 1969, carrying Commander Neil Armstrong, Command

Module Pilot Michael Collins and Lunar Module Pilot Edwin “Buzz” Aldrin into an initial Earth-orbit of 183 by

187 kilometers (114 by 116 miles). An estimated 650 million people watched Armstrong’s televised image

and heard his voice describe the event as he took “…one small step for a man, one giant leap for mankind” on

July 20, 1969.

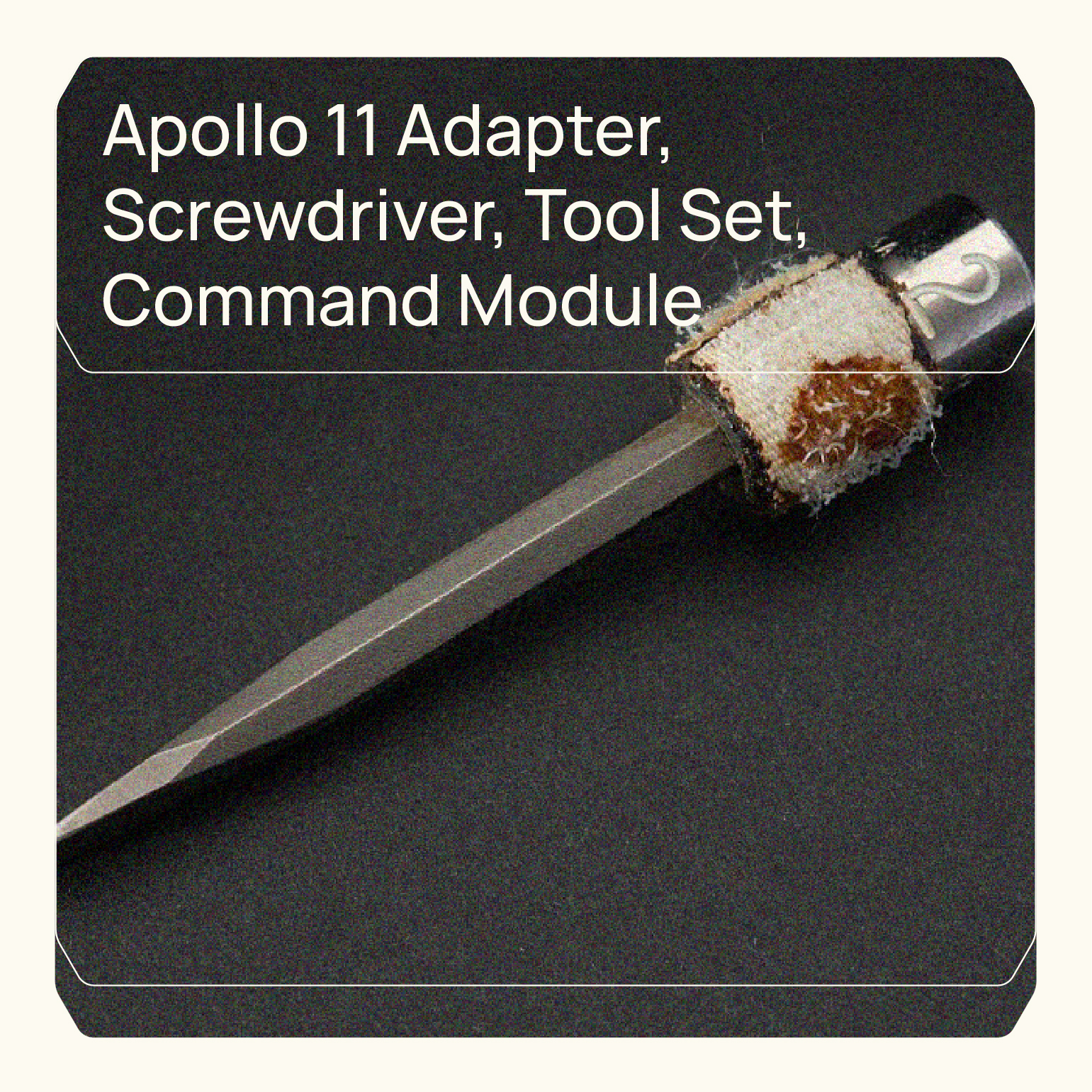

Among the tools that accompanied the astronauts on their epic voyage was the “Adapter, Screwdriver, Tool

Set, Command Module, Apollo 11.” This multipurpose kit, which included a 1/4-inch flat screwdriver labeled

“Tool 2,” was designed to torque slotted screws and bolts within the spacecraft. This tool set, now housed in

the Smithsonian, represents the meticulous attention to detail that characterized every aspect of the Apollo

program.

The workforce behind Apollo 11 extended far beyond NASA’s own ranks. 400,000 people workforce, among

them aerospace engineers, seamstresses meticulously crafting multi-layer space suits, technicians

tightening bolts at launch complex 39A, mathematicians checking and double-checking complex equations,

and parachute packers ensuring the astronauts’ safe return — all played indispensable roles in the mission’s

triumph.

As Armstrong and Aldrin descended to the lunar surface in the Eagle lander, leaving Collins to orbit alone in

the command module Columbia, they carried with them the hopes, dreams, and tireless efforts of this vast

army of supporters. Each bolt tightened, each stitch sewn, and each calculation performed had brought

them closer to this monumental moment in human history.

At Tsamouris, we dig into the history of the smallest components in achieving great feats. Just as the Apollo

tool set played a vital role in the success of the lunar landing, our fasteners and tools are designed to support

our clients in their own groundbreaking endeavors. We draw inspiration from the dedication and precision

demonstrated by the 400,000 individuals who made the impossible possible sixty years ago.