Tsamouris, the Fastener Specialists©

“How do you take the measure of a New York City more physically transformed than at any time since the

1920s? The new glass “downtowns” that have exploded in the last decade and a half in Long Island City and

over in Jersey City. Hudson Yards’ crystalline shafts to the far west. Residential towers marching in lock step

along the Queens and Brooklyn edges of the East River. The skinny supertalls slicing into the view of Central

Park.

There has never been a better time to give Gotham a fresh look, and so I headed to the exalted altitude of

New York’s first supertall: the Empire State Building, which has just spent USD 165 million (EUR 151 million)

and four years meticulously revamping the experience of getting to — and appreciating — the views from its

two vertiginous observatories on the 86th and 102nd floors. Simultaneously, its designers have tried to

banish the things visitors hate about the observation-deck trek: the lines, the crowds, the congestion.”

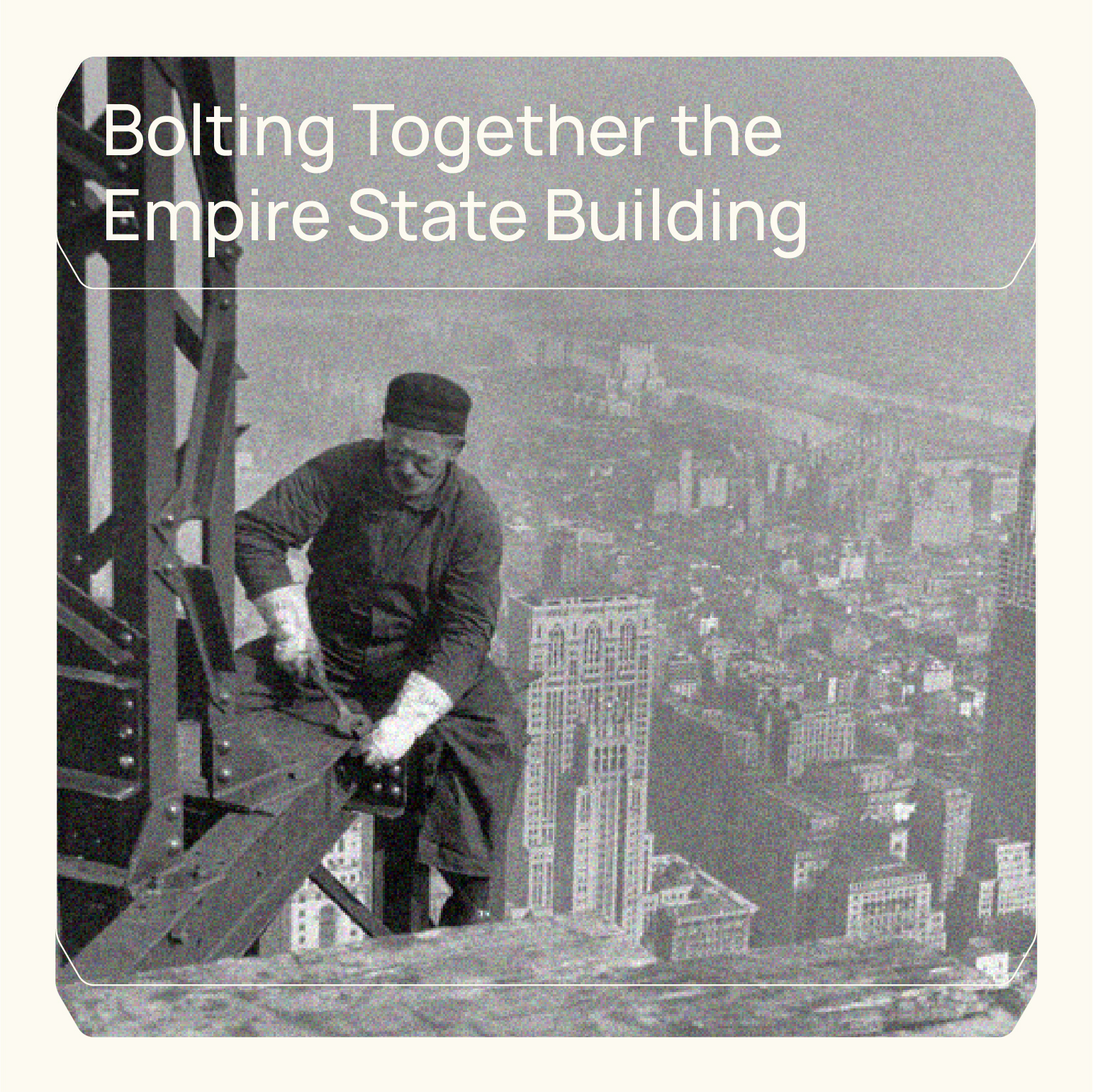

These are the words that New York Times editor, James S. Russell, used to describe the restoration of an

icon, that has captured the hearts of millions, was built with the hard work and dedication of countless

construction workers. In 1930, as the Chrysler Building loomed in the background, these brave heroes

tightened the bolts that would hold together one of the world’s most recognizable landmarks.

Some interesting facts about the Empire State Building (ESB)

1⃣ Soaring 1,454 feet (443 meters) above Midtown Manhattan, ESB has 102 floors, with 1,860 steps from

street level to the 102nd floor.

2⃣ Annually, ESB hosts its annual Run-Up event, where hundreds of athletes from around the world race a

total of 1,576 steps from the ESB lobby to the 86th Floor Observatory. The first Run-Up was held in 1978.

3⃣ ESB weighs 365,000 tons and its volume is 37 million cubic feet (1 million cubic meters).

4⃣ The exterior is composed of 200,000 cubic feet (5,663 cubic meters) of Indiana limestone

and granite, 10 million bricks and 730 tons of aluminum and stainless steel.

5⃣ Following groundbreaking, construction of the ESB took only one year and 45 days from the

setting of the tower’s first steel columns on April 7, 1930, to the completed building by March 31, 1931 — a

full month before the official opening ceremonies. This is the fastest construction to date for a project of its

scale.

6⃣ Famework rose at a rate of 4.5 stories per week.

7⃣ ESB was erected on the site of the original Waldorf-Astoria Hotel.

8⃣ More than 7 million man hours were logged in the ESB’s construction.

9⃣ ESB’s restored historic celestial ceiling mural is made of aluminum leaf and 23-karat gold.

🔟 All of the materials used on the replicated ceiling are the original materials used to create the lobby

ceiling in 1931, with over 20,000 man hours spent on the project.

1⃣1⃣ 12,000 linear feet (3,657 meters) of cast glass light fixture lenses were recreated to line the ESB lobby

and side corridor.

1⃣2⃣ The ceiling mural used over 15,000 square feet (1,393 square meters) of canvas and 115,000 sheets of

aluminum leaf.

1⃣3⃣ A series of initiatives are reducing ESB’s energy consumption by more than 38% and save an

estimated USD 4.4 million (EUR 4 million) per year on energy costs.

1⃣4⃣ On the clearest of days, visibility from the Observatories is 80 miles (129 kilometers), with five states in

view — New York, New Jersey, Pennsylvania, Connecticut and Massachusetts.

1⃣5⃣ It has been “home” to some of the most famous movies, including King Kong, An Affair to Remember,

and Sleepless in Seattle.

1⃣6⃣ The first light to shine atop the ESB was a beacon that announced that Franklin D. Roosevelt had been

elected President of the United States in November 1932.