Tsamouris, the Fastener Specialists©

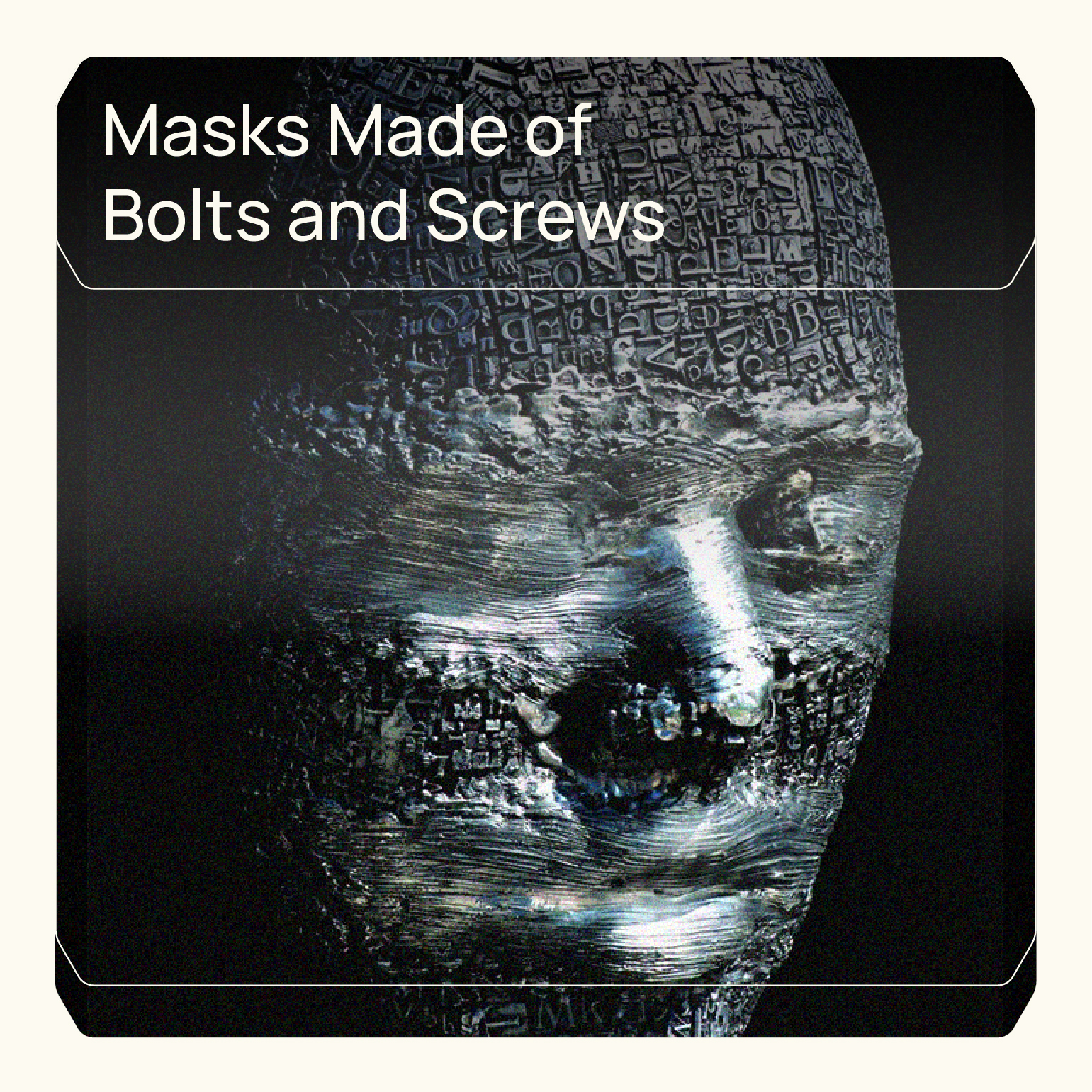

Ontario-based artist Dale Dunning has found a truly unique way to express the power of communication and

knowledge. His mesmerizing bronze and aluminum sculptures combine the art of typography with the

intricacy of welding and fasteners, resulting in a series of captivating metallic masks.

Each androgynous face is meticulously crafted from hundreds of typefaces, creating a figurative stamp that

symbolizes the essence of human interaction. But Dunning doesn’t stop there; he pushes the boundaries of

texture by incorporating thousands of bolts, screws, and washers into his creations, adding a layer of

industrial charm to these already stunning pieces.

For Dunning, the head is the perfect canvas to explore the depths of the human mind. “We live in our heads,

see, feel, and experience the world in our head,” he explains. By focusing solely on the head, he eliminates

the distraction of limbs and the rest of the body, allowing the viewer to fully immerse themselves in the

sculpture’s message.

As you gaze upon these masks, you can’t help but feel a sense of awe at the level of detail and craftsmanship

that goes into each piece. The juxtaposition of delicate typefaces and rugged bolts creates a visual

symphony that is both thought-provoking and aesthetically pleasing.