Tsamouris, the Fastener Specialists©

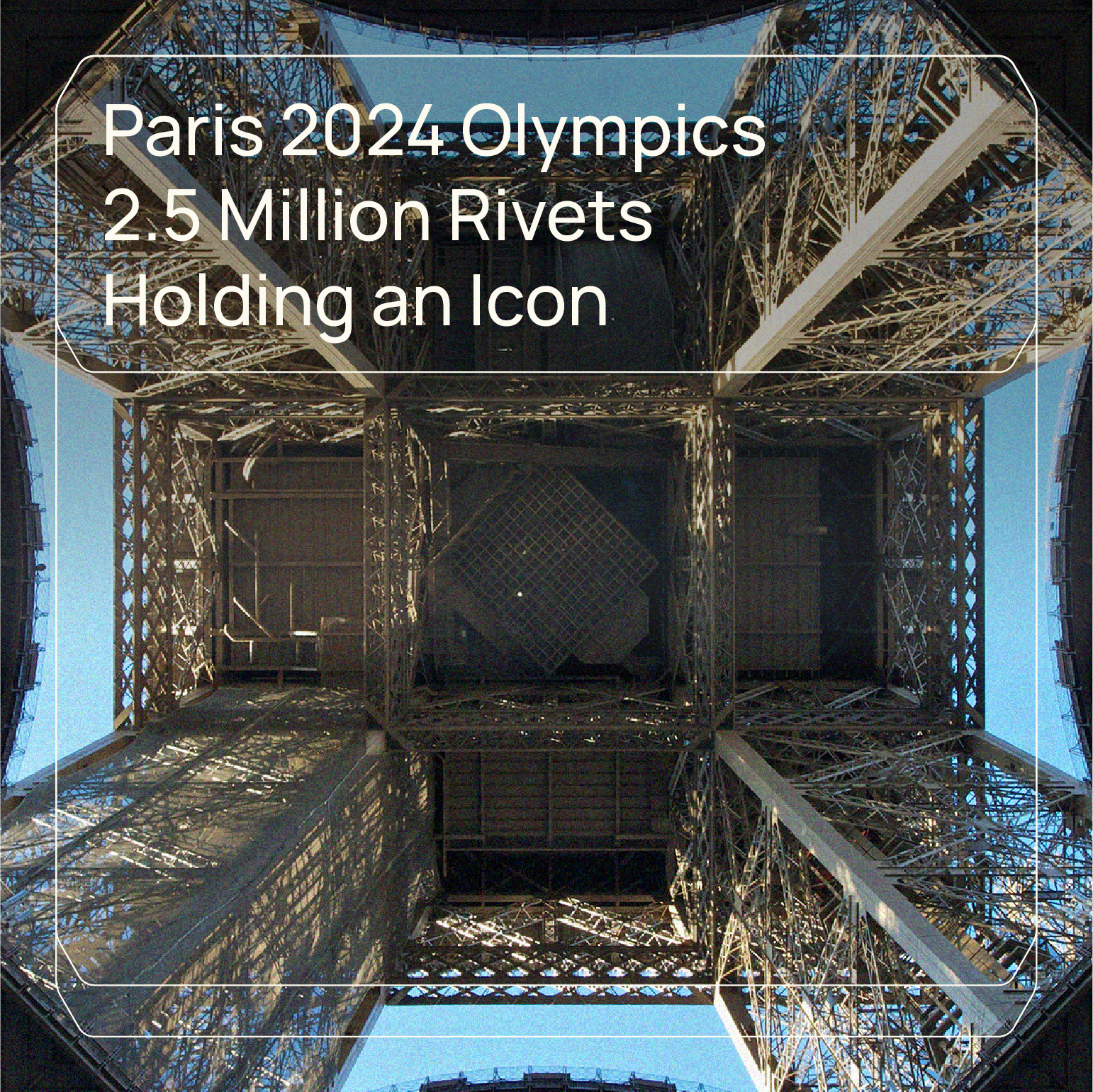

As the 2024 Paris Olympics unfold, besides the athletes, all eyes are on the Eiffel Tower. Held together by an

astounding 2.5 million rivets, this marvel of engineering shines even brighter during the Games, as it

receives a special golden paint job to commemorate the occasion.

The construction of the Eiffel Tower relied on a riveting technique that has become the monument’s

trademark. The process involved a team of four skilled riveters working in perfect harmony. One heated the

rivet, another held it in place, a third formed the head, and the final member of the team locked it in place

with a sledgehammer. This efficient method allowed for the tower to be assembled in a record-breaking time

of just two years, two months, and five days.

Many of the tower’s components were pre-assembled at a workshop in Levallois-Perret before being

transported to the site for final assembly. This approach not only streamlined the construction process but

also ensured the highest level of precision and quality control.

In total, the Eiffel Tower comprises 18,000 metal parts, held securely by 13,000 bolts and the aforementioned

2.5 million rivets. Despite the tower’s original design life of just 20 years, the use of high-quality materials

and the dedication to regular maintenance and replacement of various pieces have allowed it to stand tall for

over a century.

Here are 17 mind-blowing facts and figures about the Eiffel Tower

1⃣ Gustave Eiffel built the tower because he won a competition.

2⃣ Eiffel had to pay for much of the build himself.

3⃣ Eiffel didn’t work alone; a team of engineers, architects, and workers contributed.

4⃣ The Eiffel Tower was once the tallest structure in the world.

5⃣ It changes height due to temperature fluctuations.

6⃣ It gets a regular lick of paint, using a special “Eiffel Tower Brown” color.

7⃣ It has over 1,700 steps.

8⃣ The first guided climbing tours launched in 2017.

9⃣ The elevators travel 2.5 times around the Earth every year.

🔟 You can see beyond Paris from the top on a clear day.

1⃣1⃣ In 1909, the tower was going to be demolished but was saved by Gustave Eiffel.

1⃣2⃣ It has 7 million visitors a year.

1⃣3⃣ It was sold by a con artist in 1925.

1⃣4⃣ It “got married” to a woman named Erica in 2007.

1⃣5⃣ The tower has 20,000 lights and sparkles for five minutes every hour after dark.

1⃣6⃣ It’s eco-friendly, producing its own electricity via hidden wind turbines.

1⃣7⃣ It was almost destroyed in WWII but was saved by a general who disobeyed orders.