Tsamouris, the Fastener Specialists©

Part Five

The completion of the Sydney Harbour Bridge in 1932 established Sydney as a truly global city, giving it a

landmark to compete with any of the modern world’s great architectural marvels. With the largest single arch

of its kind, it was as instantly recognizable as Paris’s Eiffel Tower or New York’s Chrysler Building.

The ease of crossing the harbour was immediately felt across the city. The population of the North Shore

increased, while the once-thriving ferry businesses declined. The Bridge soon became a host to various

stunts and tourist attractions, with the southeast pylon opening as a popular lookout, offering uninterrupted

views of the city and beyond.

To recoup the Bridge’s significant construction and maintenance costs, tolls were introduced, inspiring

clever workarounds from enterprising citizens. By the 1980s, the tens of millions of vehicles that had crossed

the Bridge had recouped its original cost of USD 500 million (EUR 460 million) in tolls. However, the tolls

were increased to pay for the Sydney Harbour Tunnel and ongoing maintenance costs.

Each year, a team of skilled workers labors for 200,000 hours to keep the Bridge in sound working order, with

the intention of maintaining it for a thousand years. The exposed parts of the Bridge are repainted every five

years, requiring 30,000 liters of its trademark steel-grey paint.

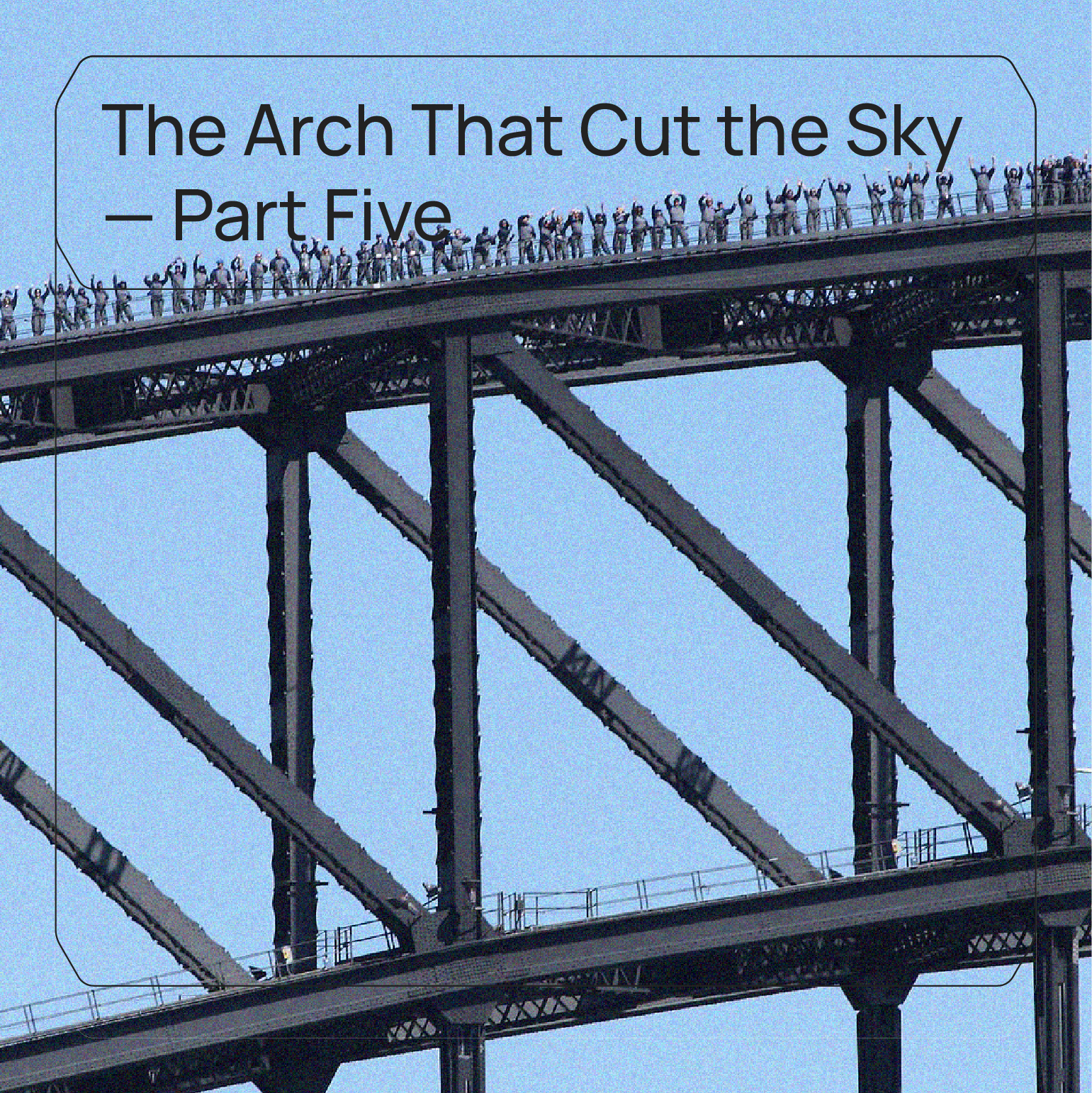

The Bridge has always attracted thrill-seekers determined to climb it, legally or not. For the last twenty years,

the slightly less adventurous have been able to take the guided Harbour Bridge Climb over the arches, with

the summit inspiring more than a few marriage proposals.

Over its 86 years, the Bridge has been a site of protest, civil action, and celebration in Sydney, with its first

closure in 1946 to celebrate Victory Day at the end of World War Two. In May 2000, a record-breaking

250,000 Australians of Indigenous and non-Indigenous descent marched across the Bridge in the historic

Walk for Reconciliation, acknowledging the dispossession of Australia’s First Nations peoples.

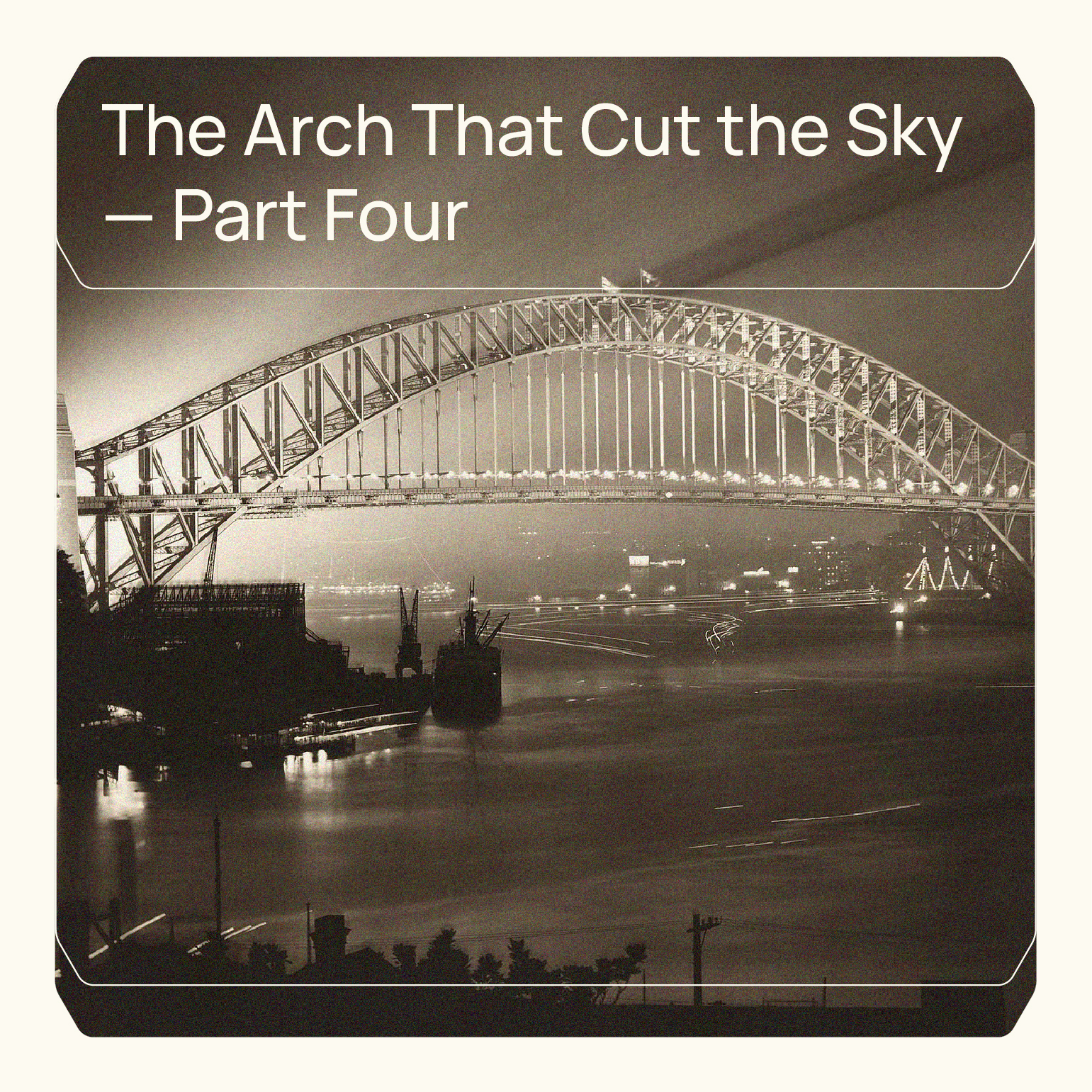

Sydney is among the first places on Earth to welcome a new year, and staking out a prime viewing spot to

celebrate the New Year’s Eve fireworks display on the Harbour has become a cherished tradition. The two

spectacular pyrotechnics shows at 9 pm and midnight take months to plan, with eight tonnes of rockets

exploding in the sky over the Harbour, cascading down the Bridge in a raucous celebration of life.

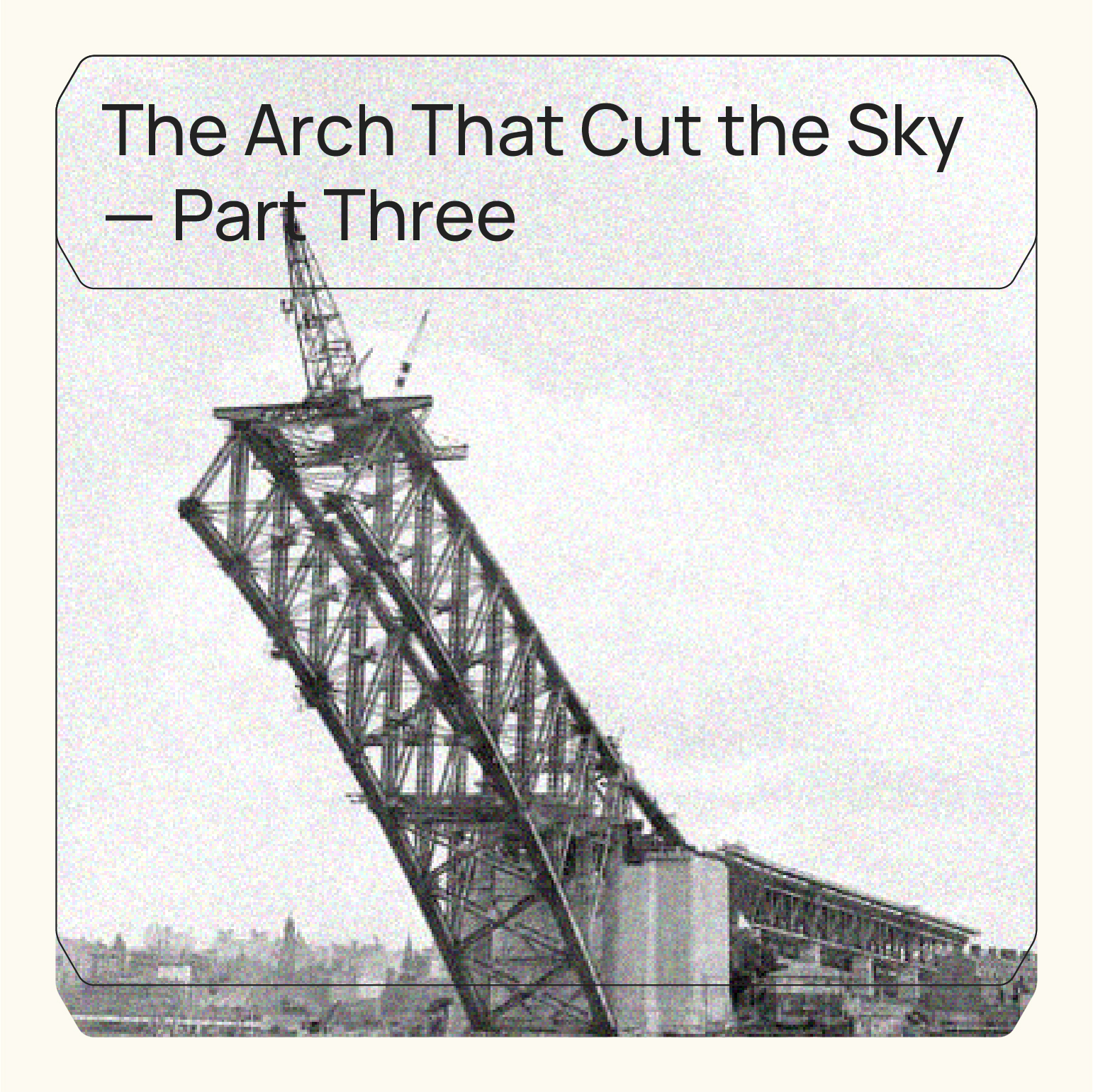

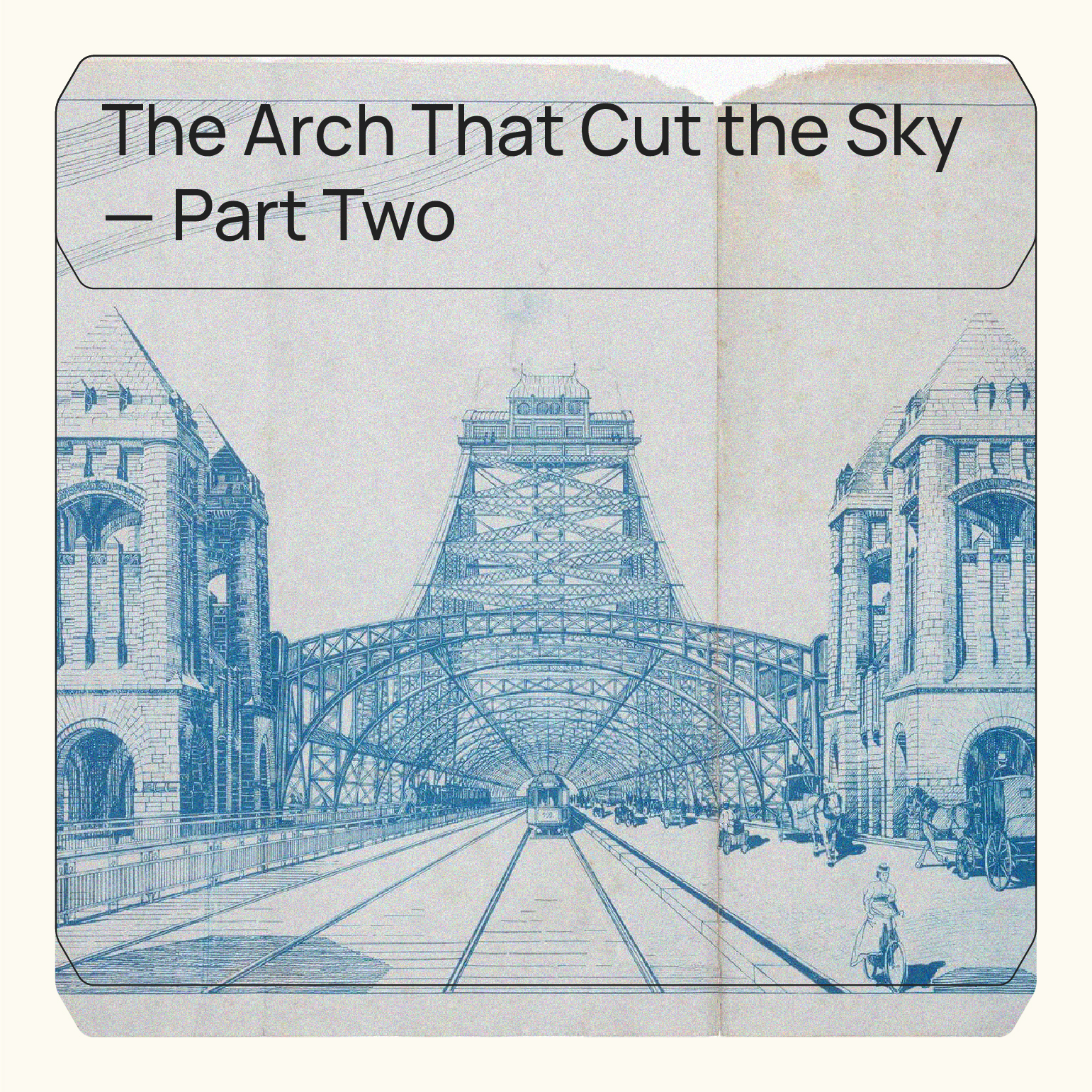

The building of the Bridge played a significant role in the technical revolution of the 1930s, seen as evidence

of Australia’s industrial maturity in the mechanical age. It displaced the pastoral and agricultural way of life,

ending the horse and buggy era, and introduced the age of steel bridges, commuter trains, and cars.

Today, the Harbour Bridge sits in a redefined Sydney as a symbol of pride and national identity, holding a

deep emotional resonance for many Sydneysiders. As the writer Ruth Park described, “…[it] hangs there like

the ghost of the wheel of fate, in a sky brindled with sunset, until darkness comes and vanishes away this

remarkable shape, which is above all things, that sign of Sydney.”

The story is based on the podcast series “The Bridge: The Arch that Cut the Sky,” created with the support of

the State Library of New South Wales Foundation. You can support it by listening at the

thebridge.sl.nsw.gov.au.

Please note that the photographs used in this story are sourced from the State Library of New South Wales

Foundation website for the podcast. These images are not our intellectual property and are used solely for

non-commercial purposes.